In the design process, many designers like to pursue the cascading of different textures and reflections expressed by a variety of materials. Among the rapidly changing decorative materials, stainless steel materials have always been one of the ways designers use to extend limited space. Stainless steel itself is a cold and hard material, but it can make the space show exquisite and elegant temperature. This is the romance of stainless steel materials.

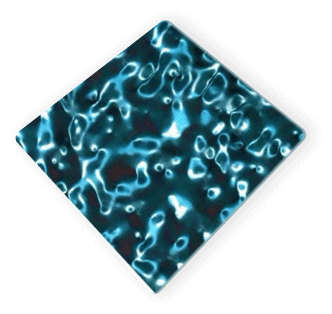

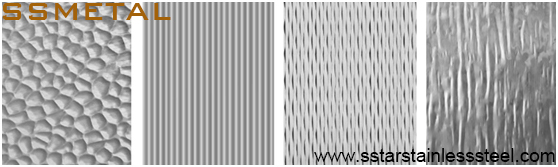

In recent years, when water rippled stainless steel enters the public’s vision, stainless steel decorative materials have once again ushered in a wave of innovative use, especially stainless steel in various forms using “embossed” processes. When it is matched with suitable lighting, the sparkling effect makes the whole space more empty and transparent. It greatly deepens the sense of depth of space.

Embossed stainless steel plate is a kind of exquisite concave and convex patterns on the surface of a metal sheet through large CNC mechanical equipment and precision pattern molds.

Stainless steel embossed sheet has the advantages of corrosion resistance, scratch resistance, wear resistance, strong decoration effect, anti-fingerprint resistance, etc. It is generally suitable for indoor ceilings, decorative elevator walls, architectural decoration, building curtain walls, etc.

In recent years, the water rippled stainless steel plate, an Internet celebrity product for interior design, squeezes the stainless steel sheet up and down through hydraulic machinery and equipment, resulting in a concave, bumpy and undulating multi-level wave structure on the surface.

Characteristics of embossing stainless steel sheet

Compared with other decorative materials, the stainless steel embossed sheet has many styles, durable, rich colors, strong three-dimensional sense, and also has safety, environmental protection, fire protection and other properties.

The properties of stainless steel plates are very stable and will not change their properties due to the moisture in the air.

In addition, it is hard and more durable. The pattern is stamped on the stainless steel plate to form a metal embossed sheet, and its three-dimensional visual sense is immediately presented in front of you.

A. Good environmental adaptability

Embossed stainless steel is waterproof, fireproof, acid-base-proof, high melting point, not easy to burn, strong toughness and not fragile, and not easy to corrode in an air acid-base environment.

Compared with traditional exterior wall insulation boards, metal embossed sheets have better cold resistance and thermal insulation.

B. Good safety performance

Stainless steel embossed plate is radiation-free, safe and environmentally friendly, and easy to clean.

It is shock-resistant and crack-resistant and has a longer service life. It has very good impact resistance and is used outside of the building, which can greatly reduce its impact on the building. Especially in some buildings with light steel structures, it is particularly suitable for using embossed stainless steel panels.

C. Strong shaping

Due to the good toughness of stainless steel, various shapes can be made using welding, brushing, bending, polishing and other processes.

D. Good decoration effect

The surface is clean, bright and unique. It has a typical metal fashion art sense, embossed sheet is available in a variety of colors, and there is no need to worry about fading.

E. Environmental secondary use

Stainless steel primary color is stable, insoluble and oxidized, it can be recycled and has a certain value preservation value.

There is no chemical interference in the reinforcement process, and the impact on the environment is relatively small, and replacing wood can protect the environment and reduce wood logging.

F. High-end customization

There are many pattern structures of embossing stainless steel, which can provide customized services and design unique styles of patterns according to the requirements of consumers to meet the needs of the majority of users.

Classification of stainless steel embossed sheet

Stainless steel embossed sheets can be divided into two categories according to the production process:

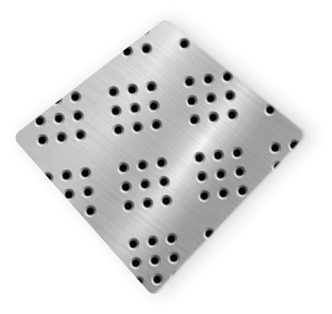

Die stamping

Sheet processing, local force;

Die stamping is frequently stamped by pattern on the plate, so the depth and three-dimensional feeling of the die stamping pattern are stronger than the rolled pattern.

Reel embossing

Reel processing, average force;

Reel embossing is the whole rolled on the embossing roller through the winding machine, so the flatness of the roller embossed plate is better than that of the stamping plate.

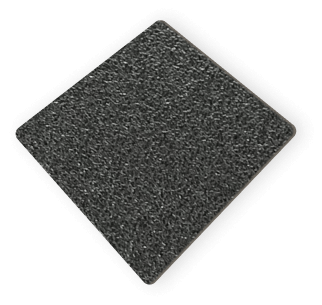

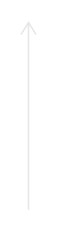

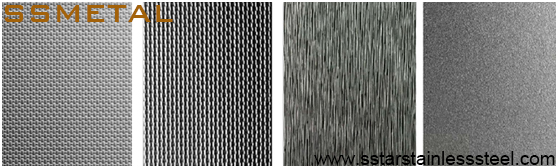

Stamped stainless steel plates can be divided into the following categories according to their appearance:

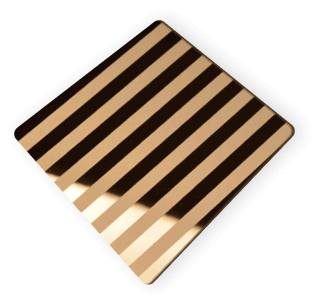

Single-sided series:

Process: Under the working condition of a single pattern mold through roller pressing machinery and equipment, the stainless steel coil is put on it up for extrusion, so that the front is concave and convex pattern, and the reverse side is flat.

Double-sided series:

Process: Through roller pressing machinery and equipment, under the working condition of two cylindrical pattern molds, the stainless steel sheet is extruded on both sides, so that the front and back sides are in the form of concave ups and downs, commonly known as double-sided embossed patterns.

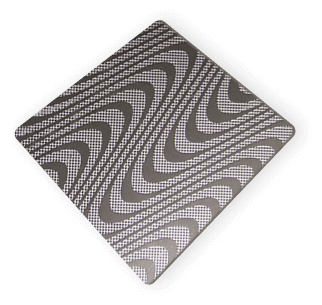

Water wave series:

Process: The stainless steel sheet is extruded up and down through hydraulic machinery and equipment, so that there is a concave and bumpy multi-layer pattern structure on the surface.

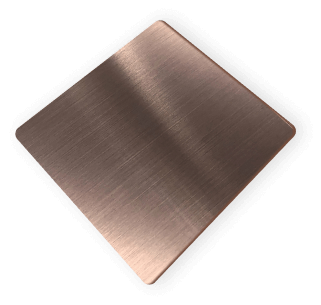

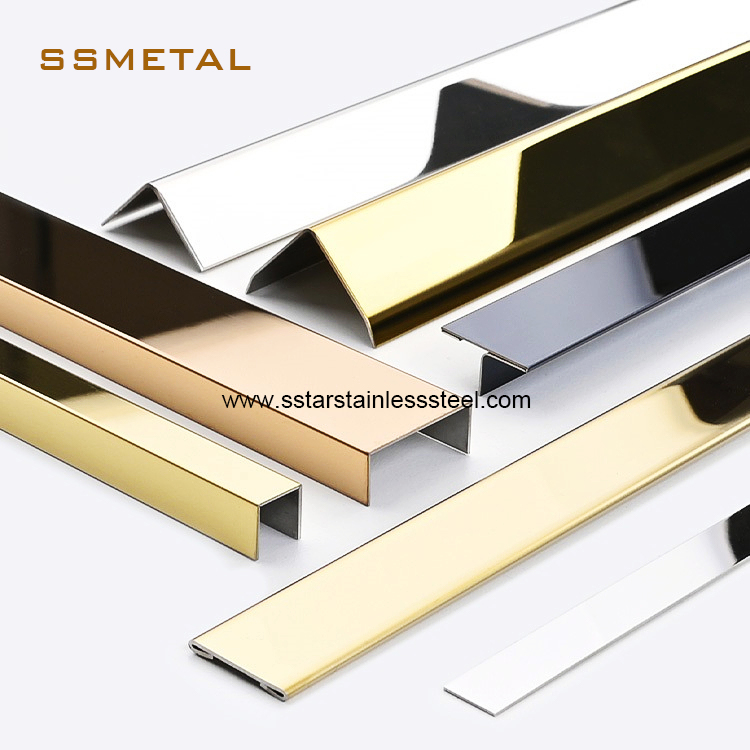

The surface coloring process of stainless steel can bring different colors to stamped stainless steel, making the metal more colorful, and can also effectively improve the wear resistance and corrosion resistance of the product.

The commonly used surface coloring methods of stamped stainless steel sheets mainly include: electrolytic coloring, retro old, and vacuum titanium plating.

The main colors produced are: champagne gold, rose gold, gold, black, blue, copper, bronze, etc.

At present, there are many types of embossed plates on the market. Commonly, such as beaded patterns, small plaids, diamonds, stripes, antique plaids, chrysanthemums, free grains, European patterns, wood grains, rice grains, etc.