Source: advanced engineering group

Everyone is familiar with iron, carbon, and steel. Iron and carbon are the basic chemical elements of which metal steel consists. As small as a pair of scissors, as large as a spaceship, these inventions are inseparable from the use of steel.

Steel is actually a huge family of metal alloys. With professional methods, steel can be divided into different types. For example, according to the amount of chemical element carbon, steel can be divided into mild steel (C≤0.25%), medium carbon steel (C≤0.25~0.60%) and high carbon steel (C≤0.60%).

There are many factors to consider when choosing carbon steel or stainless steel, such as hardness, price, applications and so on. Sometimes consumers also need to take the manufacturer and supplier into account.

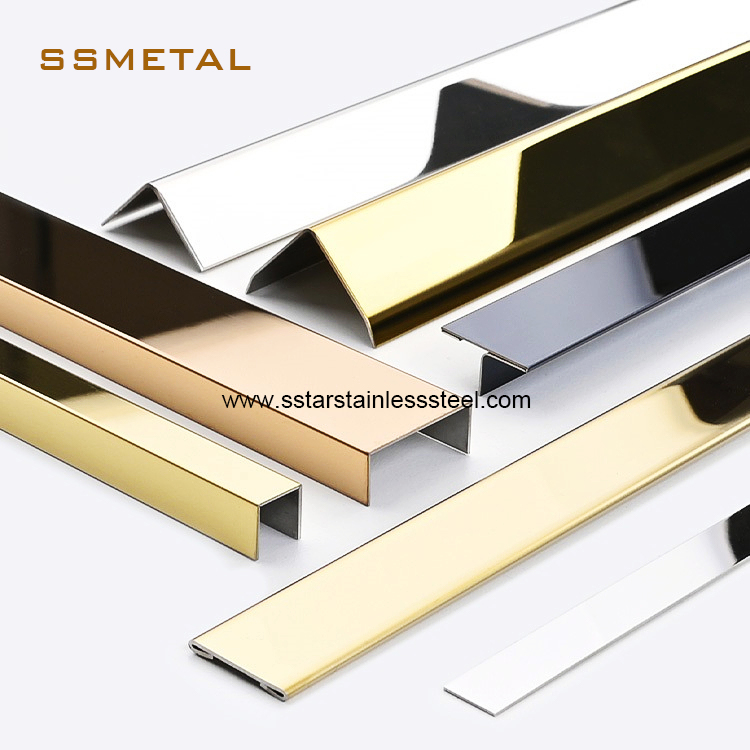

For example, as a stainless steel supplier, SSMETAL is famous for its diverse stainless steel product including large sheets, coils, strips, pipes, and profiles. The goal of SSMETAL is to provide consumers with high-quality stainless materials. SSMETAL is also one of the best stainless steel sheet supplier since it has precise cutting and slitting technology to adapt to different requirements for size.

This article will briefly discuss two common types of steel: stainless steel and carbon steel and compare their difference with respect to hardness, elasticity, weight, price, and applications.

Carbon Steel and Its Four Types

Carbon steel is an iron carbon alloy with carbon content ranging from 0.0218% to 2.11%. This type of steel also contains small amounts of silicon, manganese, sulfur and phosphorus. For carbon steel, the higher the carbon content, the greater the hardness and strength, but the lower the plasticity.

There are four general categories of carbon steel: low, medium, high, and ultra high.

Low-carbon steel with typically under 0.30% carbon is easily formable and often used in pipe, wire, and general hardware.

Medium carbon steel has the carbon content of between 0.31% and 0.6%. This type of steel is much stronger and used in railroad applications, mechanical parts, and other similar applications.

The carbon content of high-carbon steel is between 0.61% and 1%. It is most often used in high tensile strength or wear applications such as blades and springs.

Ultra-high-carbon steel has approximately 1.25–2.0% carbon content. It can be tempered to great hardness.

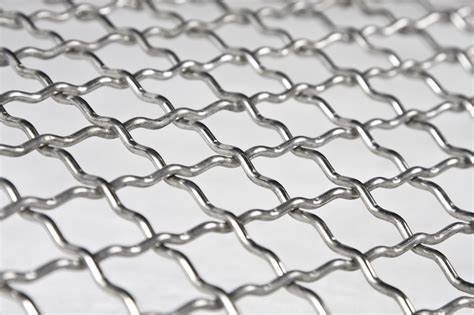

Stainless Steel and Its Five Types

Stainless steel contains iron, carbon, and at least 10.5% chromium. Chromium is the key component of stainless steel. It reacts with oxygen to form a passivation layer that protects the steel from corrosion.

There are more than 100 grades of stainless steel the majority of which are classified into five groups: austenitic, ferritic, martensitic, duplex, and precipitation-hardening.

With 16 to 26 percent chromium and up to 35 percent nickel, austenitic steels usually have the highest corrosion resistance. They are not hardenable by heat treatment and are nonmagnetic. The most common type of austenitic steel is the 18/8, or 304 grade, which contains 18 percent chromium and 8 percent nickel. Typical applications include aircraft and the food-processing industries.

Standard ferritic steels

It contains 10.5 to 27 percent chromium and is nickel-free. It is due to the low carbon content (less than 0.2 percent) that ferritic steels are not hardenable by heat treatment and have less critical anticorrosion applications, such as architectural and auto trim.

Martensitic steels

usually contain 11.5 to 18 percent chromium and up to 1.2 percent carbon with nickel added. They are hardenable by heat treatment, have modest corrosion resistance, and are applied to the production of cutlery, surgical instruments, wrenches, and turbines.

Duplex stainless steels

It is a combination of austenitic and ferritic stainless steel in equal amounts. It means that duplex stainless steels contain 21 to 27 percent chromium, 1.35 to 8 percent nickel, 0.05 to 3 percent copper, and 0.05 to 5 percent molybdenum. Duplex stainless steels are stronger and more resistant to corrosion than austenitic and ferritic stainless steels, which are useful in storage-tank construction, chemical processing, and containers for transporting chemicals.

Precipitation-hardening stainless steel

It usually contains 15 to 17.5 percent chromium, 3 to 5 percent nickel, and 3 to 5 percent copper. This type of stainless steel is famous for its strength because of the addition of aluminum, copper, and niobium to the alloy in amounts less than 0.5 percent of the alloy’s total mass. Often used in the construction of long shafts, it is comparable to austenitic stainless steel in terms of corrosion resistance.

Comparison

Source: monroeengineering

Hardness

In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Hardness is probably the most poorly defined material property because it may indicate resistance to scratching, resistance to abrasion, resistance to indentation or even resistance to shaping or localized plastic deformation. Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness.

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from Brinell, and W from the material of the indenter, tungsten (wolfram) carbide). In former standards, HB or HBS were used to refer to measurements made with steel indenters.

High-carbon steel is so hard and wear-resistant that can withstand a lot of force before it deforms. Unfortunately, hard metals are also brittle. High-carbon steel is more likely to crack than bend when placed under extreme tensile stress. In stainless steel, chromium can be used as a hardening element and is often used in conjunction with toughening elements such as nickel to produce excellent mechanical properties.

Some common materials and their Brinell Hardness

| Material | Brinell Hardness Number – HB (MPa) |

| Lead | 5.0 |

| Copper | 35 |

| Soft Brass | 60 |

| Ferritic stainless steel | 180 |

| Stainless steel – 304 | 201 |

| Duplex stainless steel | 217 |

| Precipitation hardening steels | 353 |

| White cast iron | 415 |

| Glass | 1550 |

Elasticity

Young’s modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. Up to a limiting stress, a body will be able to recover its dimensions on the removal of the load. The applied stresses cause the atoms in a crystal to move from their equilibrium position. All the atoms are displaced the same amount and still maintain their relative geometry. When the stresses are removed, all the atoms return to their original positions and no permanent deformation occurs.

Young’s modulus of elasticity of high-carbon steel is 200 GPa, and austenitic stainless steel is 45 GPa. The steel young modulus is a measure of its stiffness/ resistance elastic deformation to tensile loads. The reason for differing values of young’s modulus of steels is due to the manufacture process, which accounts for the amount of impurities in the steel and the type/ grade of steel specified.

Durability

Carbon steel can rust in some conditions because it lacks the corrosion resistance of its stainless steel counterpart. Although carbon steel is stronger than stainless steel, it may rust and corrode when exposed to moisture. Even small amounts of moisture, including wet vapors in the air, can cause carbon steel to rust.

Carbon steel is less ductile than stainless steel. Stainless steel is generally more malleable than carbon steel, mainly because of its higher nickel content. But certain stainless steels are very brittle, like martensitic stainless steel.

Weight

Steel is a deformable material, so the properties and weight of steel can be affected under different conditions. The theoretical weight of steel refers to the weight per unit length of material of specific length and thickness. In the calculation of theoretical weight, in addition to the outside diameter and thickness indicated by the specification, the features of the material also need to be considered, such as metal type, element content and specific gravity.

The density of stainless steel is about 7.9 g/cm3. The weight of stainless steel per cubic inch is 0.285 pounds, and per cubic foot is 490 pounds. The typical density for carbon steel plate is 0.284 pounds per cubic inch. The weight of carbon steel per cubic foot is 490 pounds in imperial or 7.85 cubic meters in metric.

Price

The price of steel is determined by many variables such as supply, demand, and energy prices. Raw materials prices change daily. However, generally speaking, stainless steels cost four to five times much as carbon steel in material costs. Carbon steel is about $500/ton, while stainless steel costs about $2000/ton.

Stainless steel is more expensive than carbon steel because other alloys, such as chromium, nickel, and manganese, are added to the process of making stainless steel. Using these extra elements adds to the cost. Compared with stainless steel, carbon steel is mainly made up of relatively inexpensive iron and carbon. Carbon steel is therefore cheaper to produce. If the budget is tight, carbon steel may be the best choice.

When purchasing appliances and other large items, it is important to pay attention to the stainless steel grade. Not all stainless steel has the same price. Stainless steel with a minimum chromium content of 10.5% is much cheaper and less durable than stainless steel with a chromium content of 16%. The price difference will show up later in maintenance costs and service life.

Application

The most commonly used form of steel is carbon steel. Up to 90% of the steel produced today is carbon steel. Wide availability, range of properties, and cost make this form of steel ideal for manufacturing, construction, transportation, and industrial uses.

Typical applications for low-carbon steel include automobile body components, structural shapes, and sheets that are used in pipelines, and buildings.

Medium-carbon Steel is mostly used in the production of machine components, shafts, axles, gears, crankshafts, coupling and forgings and could also be used in rails and railway wheels.

High-carbon steels could be used for springs, rope wires, hammers, screwdrivers, and wrenches.

Ultra-high-carbon Steel could be used for hard steel products, such as truck springs, metal cutting tools, and other special purposes like (non-industrial-purpose) knives, axles, or punches. Most steels with more than 2.5% carbon content are made of powder metallurgy.

In spite of the diverse types of stainless steel, only a dozen or so are regularly used.

For example, AISI Type 304 SS, having a chromium-nickel constituent and low carbon, is popular for its good corrosion resistance, cleanability, and formability, making it popular for many everyday items such as kitchen sinks.

AISI Type 316 SS, containing the alloying element molybdenum, is even more resistant to chemical attack than Type 304, making it useful for exposure to seawater, brine, sulfuric acids, and other corrosives found in the industrial environment.

In general, stainless steel is typically used in either corrosive or high-heat environments. High levels of chromium and nickel give stainless steel its unique properties to handle these environments. Common applications are kitchen utensils, saltwater applications, and automotive exhaust. Stainless steel is also found in household appliances, toolboxes, automotive wheels, and so on.

Conclusion

Source: ssmetalinox

To sum up, carbon steel and stainless steel have advantages and disadvantages in different aspects. Each type of steel varies in its properties such as hardness, elasticity, durability, weight, and price so different kinds of steel are applied to different conditions. Consumers have to take the properties of steel into their consideration when purchasing.

Carbon steel or Stainless steel? Regardless of the difference between carbon steel and stainless steel, the most important thing is that consumers should choose the type of steel that meets their demands.