Source: The Spruceeats

The invention and use of stainless steel date back to the First World War. At that time, the chamber of a gun on the battlefield was always worn out and unusable. Later, an assistant found alloy steel in the garbage, which turned out to be stainless steel resistant to acid, alkali, and salt. Nowadays, stainless steel is very common in people’s life. Different types of stainless steel are often used in different scenes. In this article, the types and applications of stainless steel will be described in detail.

What is Stainless Steel

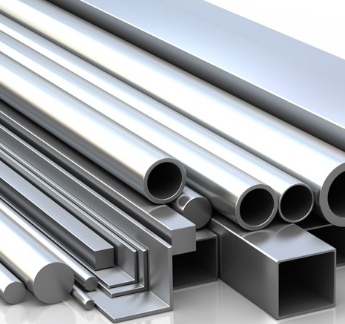

Source: Alro Steel

Stainless steel is simply an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other non-metals, and metals to obtain other desired properties. The stainability and corrosion resistance of stainless steel are due to the formation of chrome-rich oxide film on its surface. This rust resistance and corrosion resistance are relative.

The test shows that the corrosion resistance of steel in the atmosphere, water, and other weak media and nitric acid and other oxidizing media, its corrosion resistance increases with the increase of chromium content in steel, when the chromium content reaches a certain percentage, the corrosion resistance of steel changes, namely from easy to rust to not easy to rust, from corrosion resistance to corrosion resistance.

Common Compositions

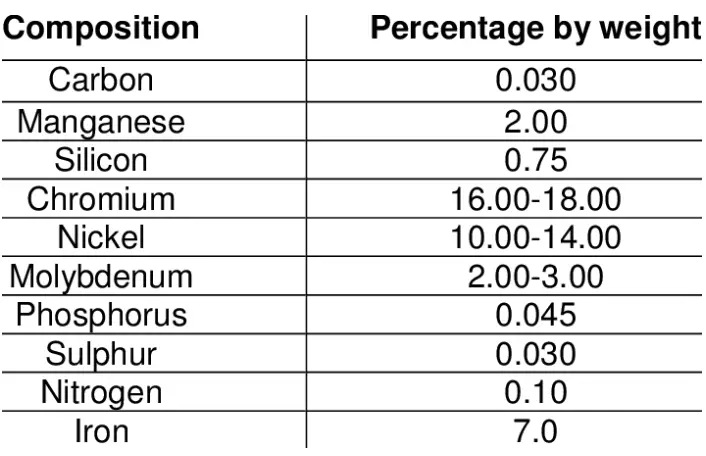

Source: ResearchGate

The main elements of stainless steel are iron, chromium, nickel, carbon, and manganese. Iron is the basic metal element of stainless steel. Chromium is the basic component of stainless steel, increasing the content of chromium, to improve the corrosion resistance of stainless steel to oxidizing acid is very effective, but also to improve the point corrosion resistance. Nickel is one of the basic elements of austenitic stainless steel. The main role of nickel in stainless steel is that it changes the crystal structure of steel. Carbon can improve the strength and manganese can improve the strength at high temperatures.

Types of Stainless Steel

Source: AZO Materials

Premium Types

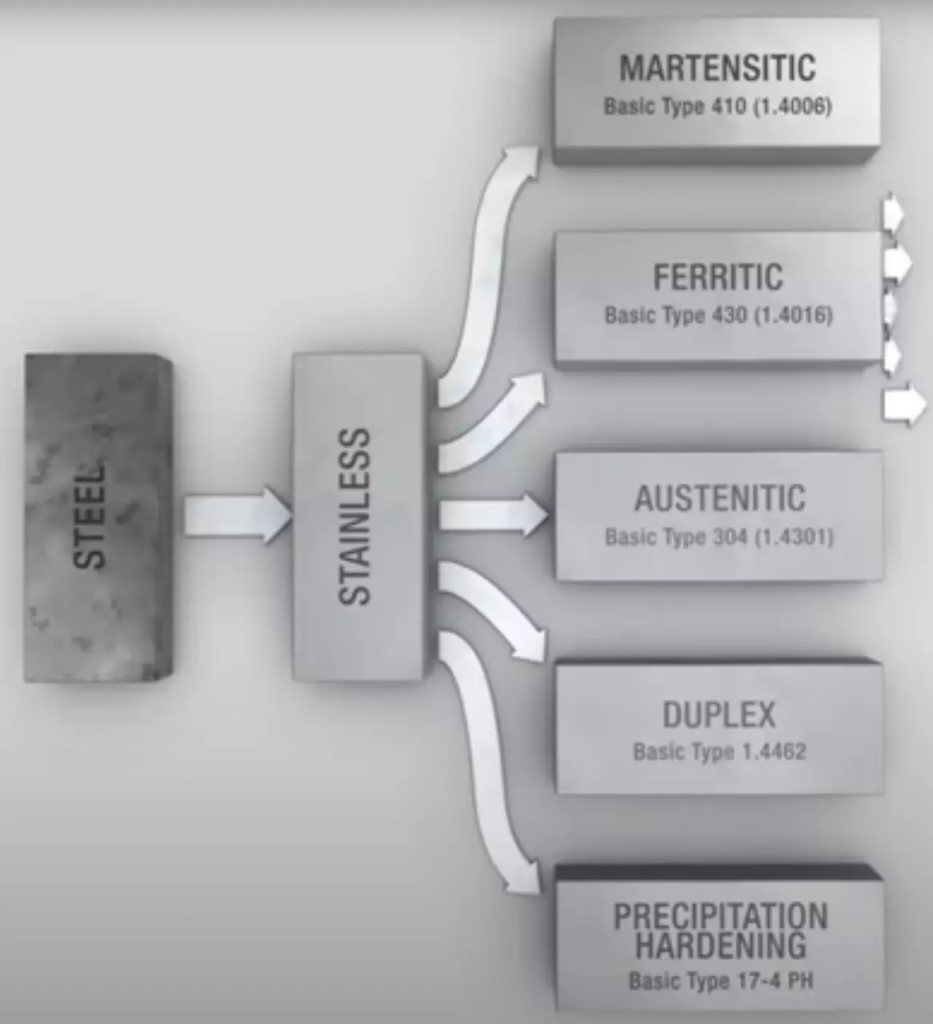

Stainless steel can be classified into one of five different types: ferritic, austenitic, martensitic, duplex (austenitic-ferritic), or precipitation.

Ferritic stainless steel

Ferritic stainless steel has a similar structure to low alloy steel and has strong corrosion cracking resistance. It contains almost no nickel, is cost-effective stainless steel, and usually contains high amounts of chromium (11.2% to 19%). It is harder to form than austenitic steel. And ferritic steel is magnetic.

Austenitic stainless steel is the most common type of stainless steel, accounting for more than 70% of the total production. It is a round stainless steel with sufficient weldability, formability, and creep resistance. Unlike ferritic steel, austenitic steel is in any case non-magnetic. When you add a lot of molybdenum (more than 6%), the steel becomes super austenite, which makes it better able to prevent crack corrosion and cracking.

Martensitic stainless steel

Martensitic stainless steel, which contains chromium, nickel, molybdenum, and carbon, makes its microstructure more brittle. Martensitic stainless steels are generally stronger than austenitic and ferritic stainless steels. Although they are relatively less formable, these alloys can be tempered in the same way as carbon steel.

Adding a small amount of nickel can improve the weldability of martensitic steel. These hybrid alloys are called biphasic alloys because their composition is approximately 50% austenite and 50% ferrite. By combining these two microstructures, you end up with a new form that has more strength than either of these. The strong composition also improves corrosion resistance and stress cracking resistance. This type is also magnetic because the proportion of ferritic alloys in the duplex steel is so large.

Precipitation-hardening stainless steel

The last type of stainless steel is precipitation-hardening stainless steel. The martensitic stainless steel is made stronger by the addition of aluminum, copper, and niobium in combination with a precipitation hardening process. It involves heat treating the metal to produce particles in the lattice, which helps stop irregularities in the microstructure and improves the overall strength of the alloy.

Different Grades of Stainless Steel

Each of the premium types of stainless steel can be subdivided into grades of stainless steel. The most popular grades of ferritic stainless steel include 409, 430, 439, and 441.

Most 300 series of stainless steel is austenitic. There are several grades such as 303, 304, 316, 321, and 347. 304 is the most commonly used austenitic stainless steel. It finds use in various industries, including automotive, food and beverage, nuclear, and shipping. 400 series of stainless steel is martensitic which includes grades 410, 416, and 440C. 410 is durable and highly resistant to wear but is more susceptible to chemical corrosion and oxidation. The material is often used in automotive parts, medical products, nozzles, pipelines, and valves.

The grades of duplex stainless steel are 2205 and 2207. Due to their high strength and corrosion resistance, they are frequently used in components for the Marine, chemical, oil, and gas industries. Precipitation hardening stainless steel is graded into categories of 13-8, 15-5, and 17-4/17-4PH. 17-4PH stainless steel contains more chromium and copper. It’s very strong and corrosion-resistant. Its uses include offshore oil and gas and nuclear waste treatment applications. It can also be found in aircraft and auto parts. 17-4 stainless steel is similar to 17-4PH but only goes through one heat treatment process during manufacturing. Therefore, it is softer but generally used for the same applications.

Common Applications of Stainless Steel

Source: Matmatch

| Grade of SS | Properties | Common Applications |

| 303 | The easiest to cut of all austenitic stainless steels. Machinability Corrosion resistance is lower than grade 304. | ShaftsNuts, bolts, and screwsGears Aircraft fittings Bushings |

| 304 | Most widely used; Contains 18% chromium and 8% nickel. Used in heavy-duty instrumentation components to improve weldability. | Appliances, Food processing equipment, Heat exchangers, Fasteners |

| 316 | The second most common. Contains about 2 to 3 percent molybdenum. This additive increases corrosion resistance | Industrial equipment, Medical equipment where non-surgical steel, Marine equipment, Food production and processing in saline environments |

| 310 | Contain 25% chromium and 20% nickel. Highly resistant to oxidation and corrosion. It is not recommended for frequent liquid quenches. | Cryogenic structures, Food processing equipment, Burners and combustion chambers |

| 321 | Heat resistance ranges up to 900°C. High phase stability and subsequent water corrosion. Not sensitive to intergranular corrosion | food industry, film and photo industry, household items, Power station construction |

Construction

Source: BuildersMART

Stainless steel was developed in the early 20th century and has proven to be an important material used in a wide range of industries as well as a range of applications. It is widely used in the construction industry. There are many reasons for choosing to use in the construction industry, including its high corrosion resistance and the fact that most stainless steel is fairly easy to manufacture. It has a range of finishes and is easy to maintain.

Stainless steel is used to provide support and strength for the structure, but in terms of architecture, steel is used for construction work that is not only needed to achieve its purpose and to be durable, but stainless steel is also ideal for creating style. The reinforcement of the building can be made out of stainless steel, which would be very costly if it were made out of other materials.

Buildings in construction need adequate structure to support them. Many parts of the supporting system are made of stainless steel, including lintels, wall starters, wind columns, and masonry supports. They are made of stainless steel tape, plates, and wire. In addition, a range of fixtures can be used, including wall nails, tie wires, screws, and nails, all made of stainless steel.

Tape & Piping

Source: Thomasnet

The stainless steel tape is a non-magnetic tape made of 304 stainless steel. It is ideal for use in decorative, Marine, food processing, and nuclear applications. It has a stainless steel substrate (which is a tape surface). The adhesive is made of acrylic and is very sticky. Padding is included on the adhesive to make the tape easier to unfold and apply.

The cheapest option is not stainless steel piping, but it is the best value for money compared to many alternatives. Staining and corrosion are major problems for most piping materials. The tube is exposed to corrosive materials both inside and outside and will wear down over time. This will gradually reduce the visibility of iron, steel, and even concrete pipes. All of these can cause cumulative damage to soil, sunlight, rust, and wear. Therefore, stainless steel is a reliable commodity that can last for decades. It is easy to install and maintain, and because it is so corrosion-resistant, it does not take long to replace or repair. That means you’ll reduce costs in the long run.

Interior Design & Art

Source: Abimis

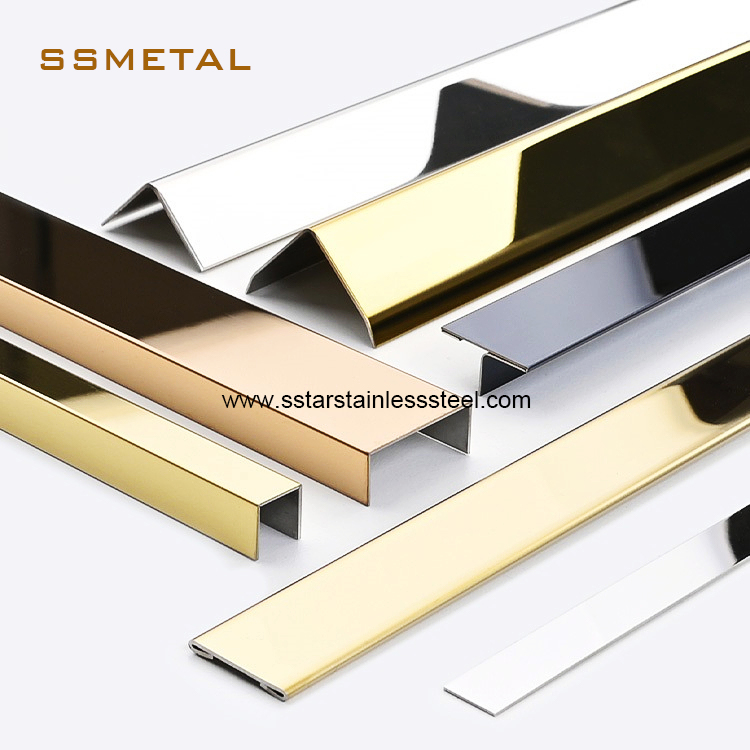

There are different stainless steel profile styles made to fit our everyday needs. Its composition is of high quality and the appearance provides enough beauty to suit any location. Therefore, it is found increasingly common in various decorative elements. Cabinets and even kitchen utensils made from this material tend to be a consumer desire for many people because of their elegance and utility. Stainless steel can be easily used in a variety of scenarios.

Food & Catering

Source: Gasparini

Machinery and tools used in the canning industry, as well as in catering and restaurants, must meet strict hygiene standards. Stainless steel is almost always the only choice for these departments due to its corrosion resistance. Each alloy has its advantages and disadvantages, forcing manufacturers to choose wisely among hundreds of stainless steel grades. What’s more, stainless steel can withstand years of regular cleaning and maintenance and still look as good as the table, surface, or equipment when it arrives.

Medical

Source: Advance Materials Supplies

Medical grade stainless steel is part of the austenitic stainless steel family, a category known for its high formability and exceptional corrosion resistance. Grade 304 and 316 stainless steel contains a large amount of nickel, which provides additional chemical properties that make them suitable for use in the extreme requirements of the medical industry. Grade 316L is particularly biocompatible with ASTM F138/F139. It is a common choice for biomedical implants, as well as body piercings and body modification implants. The immune system’s reaction to nickel is a potential complication of the body’s use of stainless steel. The austenitic stainless steel alloy with or without nickel nitrogen can solve this problem.

Aircraft & Ship Building

Source: Metal Exponents

The aerospace industry has been one of the largest consumers of stainless steel for decades. Materials used in aerospace must maintain their structural integrity. Stainless steel is used in the aerospace industry due to its resistance to corrosion and oxidation at high temperatures. In addition, it maintains its mechanical properties over a wide range of temperatures. Stainless steel is used to produce fasteners because it resists unpredictable pressure conditions and can maintain consistency in extreme temperatures. Stainless steel also has excellent heat and fire resistance, a shiny and beautiful appearance, and the best sanitary properties. Stainless steel can be used in almost all metal parts of an airplane.

The Benefits of Using Stainless Steel

Source: Ulbrich

Eco-Friendly

In the world, it is increasingly necessary to go green and ensure the highest sustainability of the world’s energy resources. The most commonly used green material is stainless steel. Stainless steel is a very environmentally friendly material as it is 100% recyclable. In fact, more than half of the stainless steel materials in use today are extracted from waste materials. What’s more, its production does not produce toxic runoff. And stainless steel alloys have no adverse health effects, so there is no danger.

Easy to Maintain

All grades of stainless steel are subject to discoloration due to surface deposition and are not completely maintenance-free. In order to maintain maximum corrosion resistance and aesthetics, stainless steel surfaces must be kept clean. Stainless steel is easy to clean. Washing with soap or mild detergent and warm water, followed by rinsing with water, is usually sufficient for household and construction equipment. If the surface is dried after cleaning, a better appearance will be obtained.

Elongated Duration

Because of their durability and longevity, stainless steel is often used for many years before being recycled. The average lifespan of stainless steel is estimated to be about 20 years, but there are examples of stainless steel that have been used for a century or more. All stainless steel still in use is a valuable source of potentially recyclable raw materials.

How to Maintain Stainless Steel

Source: Taste of Home

Cleaning Interior

For cleaning stainless steel interiors, most stainless steel interiors are concentrated in cooking areas such as the kitchen. Whether or not your home or business has a stainless steel interior, you’ll notice how fingerprints quickly become noticeable. Dirt, grease, and grime can build up quickly.

You should first look for a clean, dusty, and most importantly emery free cloth to help avoid scratching the stainless steel. One of the best ways to clean stainless steel is to use a cloth that has been rinsed with warm water and dishwashing liquid. Rinse well with ordinary warm water. Do not allow warm water to dry on stainless steel surfaces. Instead, wipe it off with an absorbent cloth. Removing any water remaining on the stainless steel will help prevent the stainless steel surface from leaving a watermark when it dries.

Cleaning Exterior

As for stainless steel exterior cleaning, signs of mild corrosion are easy to spot, but often difficult to clean and remove. Mild corrosion may occur when free iron particles remain on the surface of stainless steel or when contaminants such as chloride come into contact with stainless steel. And mild rust is the stainless steel surface or any rust on the joint is very serious. The iron particles embedded in the surface of stainless steel oxidize and leave dark colors or spots or stains.

Rust stains should be cleaned with a detergent containing phosphoric acid, oxalic acid, or sulfamic acid. After that carefully rinse the area with warm soapy water and be careful not to acid wash any of the other areas around the stainless steel.

Conclusion

Source: Ulbrich

There is a full range of stainless steel products in our daily lives. Stainless steel is not easy to corrosion, environmentally friendly, and recyclable. Stainless steel is widely used in different fields and industries. There are also many differences between different types of stainless steel. They are used in different fields and are becoming more and more popular. Although stainless steel has many benefits, it also requires people to clean it in order to better use them.