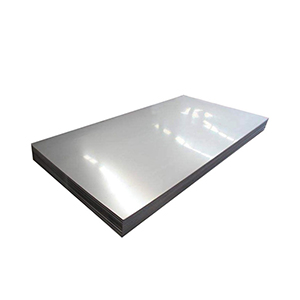

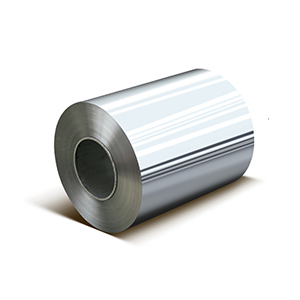

Stainless Steel Coil

- Hogar

- >

- Acero inoxidable

- >

- Bobina

Selective Coils

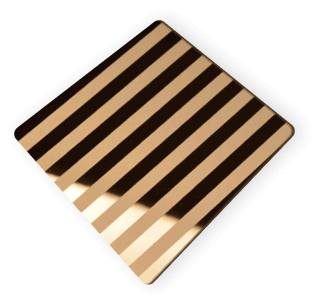

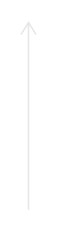

2B

No.1

licenciado en Letras

8k

Especificaciones disponibles

| Stainless Steel Coil Information | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Técnica | Acabado de la superficie | Serie de grados | Espesor(milímetros) | Ancho(milímetros) | Solicitud | |||||

| Dimensión principal | ||||||||||

| 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 | |||||

| Laminado en Caliente | No.1 /2E | 201/202/ 304 | 2.2-12.0 | Industria petroquímica Tanques Material de construcción | ||||||

| Laminado en frío | 2B | 201/304 | 0.25-3.0 | |||||||

| 410S/430 | 0.25-2.0 | |||||||||

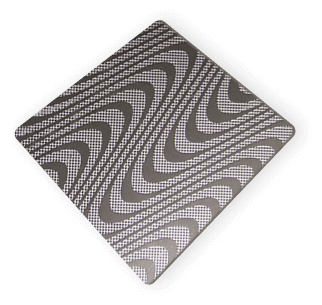

| No. 4 / Espejo rayita / Lino SB | 201/304 | 0.22-3.0 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| licenciado en Letras | 201/304 | 0.2-1.8 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| 2licenciado en Letras | ||||||||||

| Chemical composition and mechanical properties of stainless steel coil | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Calificación | Composición química (%) | Rendimiento mecánico | |||||||||

| C | Y | Minnesota | PAG | S | En | cr | Mes | Dureza | |||

| 201 | ≤0,15 | ≤1,00 | 5.5/7.5 | ≤0,060 | ≤0,030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241, HRB≤100, HV≤240 | ||

| 304 | ≤0,08 | ≤1,00 | ≤2.0 | ≤0,045 | ≤0,03 | 8.0/11.0 | 18.00/20.00 | - | HB≤187, HRB≤90, HV≤200 | ||

| 316 | ≤0,08 | ≤1,00 | ≤2.0 | ≤0,045 | ≤0,03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90, HV≤200 | ||

| 316l | ≤0,03 | ≤1,00 | ≤2.0 | ≤0,045 | ≤0,03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90, HV≤200 | ||

| 410 | ≤0,15 | ≤1,00 | ≤1,25 | ≤0,060 | ≤0,030 | ≤0,060 | 11.5/13.5 | - | HB≤183, HRB≤88, HV≤200 | ||

| 430 | ≤0,12 | ≤1,00 | ≤1,25 | ≤0,040 | ≤0,03 | - | 16.00/18.00 | - | HB≤183, HRB≤88, HV≤200 | ||

Ventaja significativa

Flexible

Convenient

Aplicaciones Típicas

Industrial Equipment

Electronic Equipment.

Kitchenware

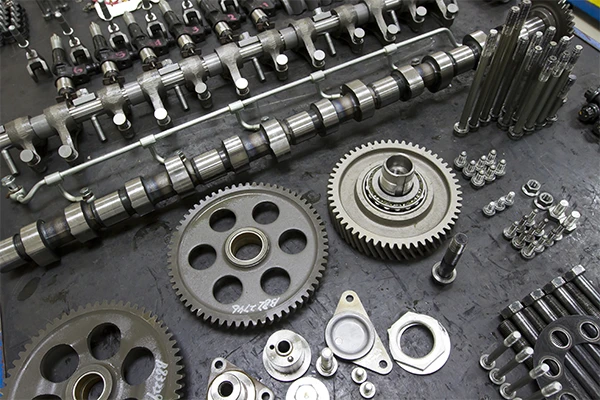

Machinery

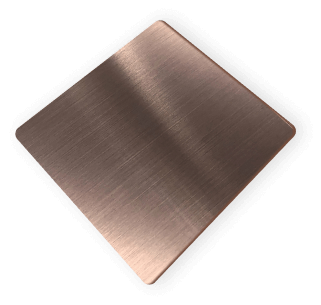

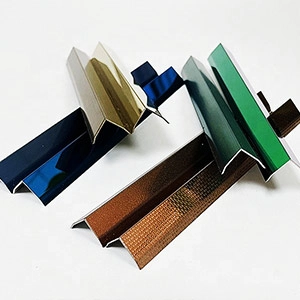

cepillado

Pulido

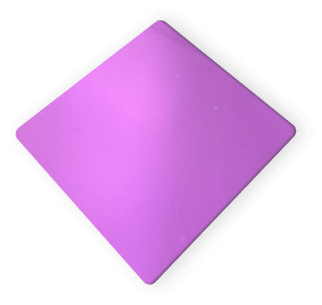

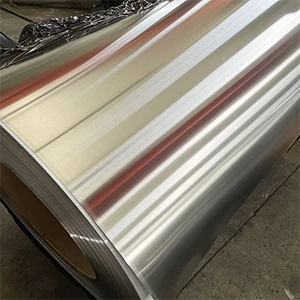

De colores

en relieve

Listo para iniciar su proyecto de personalización?

Different Grades of Stainless Steel Coils

Calificación 201 is a lower-cost alternative to 304. It offers good formability, moderate corrosion resistance, and is often used in applications that require aesthetic appeal, such as cookware, se hunde, and utensils.

Calificación 304 is the most common and widely used stainless steel grade for coils. It offers excellent corrosion resistance, buena formabilidad, and is suitable for a variety of applications in industries such as food processing, chemical, and architectural.

Calificación 316 is known for its superior corrosion resistance compared to 304. It contains molybdenum, which enhances its resistance to chemical corrosion, making it ideal for use in marine environments, pharmaceutical equipment, and coastal architecture.

Calificación 410 is a martensitic stainless steel known for its high strength, dureza, y resistencia a la corrosión. It offers good mechanical properties and can be hardened by heat treatment. Calificación 410 is commonly used in applications such as cutlery, dental and surgical instruments, and valves.

This ferritic stainless steel grade provides good corrosion resistance and heat resistance. It is commonly used in applications such as automotive trims, indoor appliances, and architectural components.

Aplicaciones comunes de la bobina de acero inoxidable

Construcción & Architecture

Industrial Machinery

Chemical & Petrochemical

Procesamiento de alimentos & Catering

Automotive and Transportation

FAQs

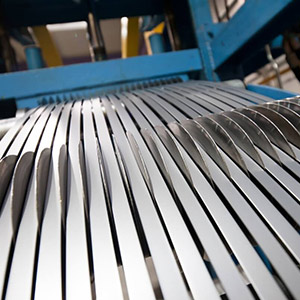

Stainless steel coil refers to a continuous strip of stainless steel that is wound into a coil shape. It is commonly used in various industries for manufacturing applications like sheet metal forming, fabrication, and as a raw material for further processing.

Stainless steel coils possess several key properties, including high corrosion resistance, strength and durability, heat resistance, hygiene and cleanability, y atractivo estético. They are also known for their low maintenance requirements and versatility in various manufacturing processes.

Stainless steel coils are typically manufactured through a process known as cold rolling. This involves passing a stainless steel strip through a set of rollers to reduce its thickness and shape it into a coil form. Cold rolling helps improve the material’s mechanical properties, dimensional accuracy, and surface finish.

Yes, stainless steel coil is highly recyclable. At the end of its lifecycle or when it is no longer needed, stainless steel coil can be collected, processed, and recycled. Stainless steel retains its properties even after recycling, and the process can be repeated multiple times without significant degradation in quality.