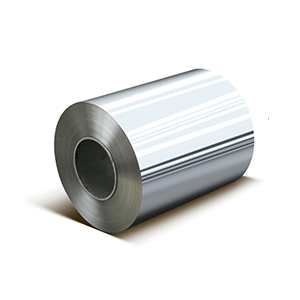

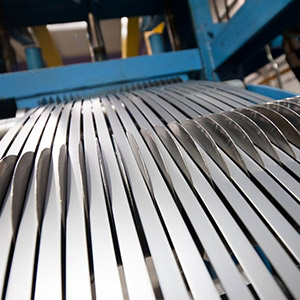

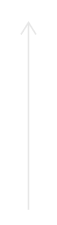

Bobine en acier inoxydable

- Maison

- >

- Acier inoxydable

- >

- Bobine

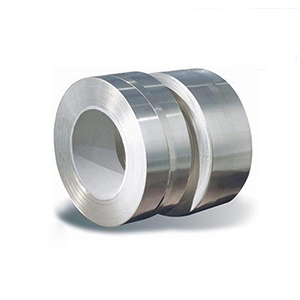

Bobines sélectives

2B

N°1

BA

8K

Spécification disponible

| Informations sur les bobines en acier inoxydable | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technique | Finition de surface | Série de qualité | Épaisseur(millimètre) | Largeur(millimètre) | Application | |||||

| Dimension principale | ||||||||||

| 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 | |||||

| Laminé à chaud | N°1 /2E | 201/202/ 304 | 2.2-12.0 | Industrie pétrochimique Citernes Matériaux de construction | ||||||

| Laminé à froid | 2B | 201/304 | 0.25-3.0 | |||||||

| 410S/430 | 0.25-2.0 | |||||||||

| Numéro 4 / Miroir délié / Lin SB | 201/304 | 0.22-3.0 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| BA | 201/304 | 0.2-1.8 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| 2BA | ||||||||||

| Composition chimique et propriétés mécaniques de la bobine en acier inoxydable | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Noter | Composition chimique (%) | Performance mécanique | |||||||||

| C | Et | Mn | P | S | Dans | Cr | mois | Dureté | |||

| 201 | ≤0.15 | ≤1.00 | 5.5/7.5 | ≤0,060 | ≤0,030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241,HRB≤100, HV≤240 | ||

| 304 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0,045 | ≤0.03 | 8.0/11.0 | 18.00/20.00 | - | HB≤187, HRB≤90,HV≤200 | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0,045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90,HV≤200 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.0 | ≤0,045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90,HV≤200 | ||

| 410 | ≤0.15 | ≤1.00 | ≤1,25 | ≤0,060 | ≤0,030 | ≤0,060 | 11.5/13.5 | - | HB≤183, HRB≤88,HV≤200 | ||

| 430 | ≤0.12 | ≤1.00 | ≤1,25 | ≤0,040 | ≤0.03 | - | 16.00/18.00 | - | HB≤183, HRB≤88,HV≤200 | ||

Avantage significatif

Flexible

Pratique

Applications typiques

Équipement industriel

Équipement électronique.

Ustensiles de cuisine

Machinerie

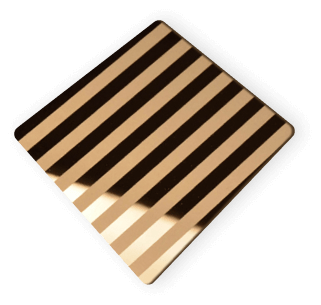

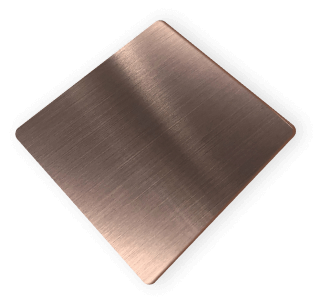

Brossé

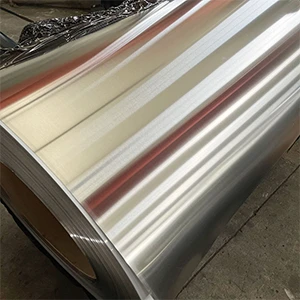

Brillant

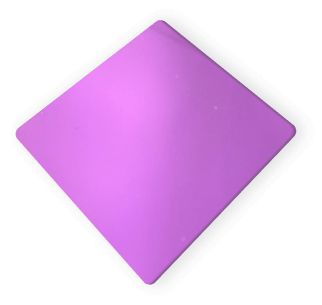

Coloré

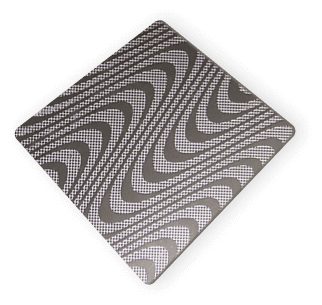

En relief

Prêt à démarrer votre projet de personnalisation?

Différentes qualités de bobines d’acier inoxydable

Noter 201 est une alternative moins coûteuse à 304. Il offre une bonne formabilité, résistance modérée à la corrosion, et est souvent utilisé dans des applications qui nécessitent un attrait esthétique, comme les ustensiles de cuisine, les puits, et ustensiles.

Noter 304 est la nuance d'acier inoxydable la plus courante et la plus largement utilisée pour les bobines. Il offre une excellente résistance à la corrosion, bonne formabilité, et convient à une variété d'applications dans des industries telles que la transformation des aliments, chimique, et architectural.

Noter 316 est connu pour sa résistance supérieure à la corrosion par rapport à 304. Il contient du molybdène, ce qui améliore sa résistance à la corrosion chimique, ce qui le rend idéal pour une utilisation dans les environnements marins, équipement pharmaceutique, et architecture côtière.

Noter 410 est un acier inoxydable martensitique connu pour sa haute résistance, dureté, et résistance à la corrosion. Il offre de bonnes propriétés mécaniques et peut être durci par traitement thermique. Noter 410 est couramment utilisé dans des applications telles que la coutellerie, instruments dentaires et chirurgicaux, et les vannes.

Cette nuance d'acier inoxydable ferritique offre une bonne résistance à la corrosion et à la chaleur.. Il est couramment utilisé dans des applications telles que les garnitures automobiles, appareils d'intérieur, et éléments architecturaux.

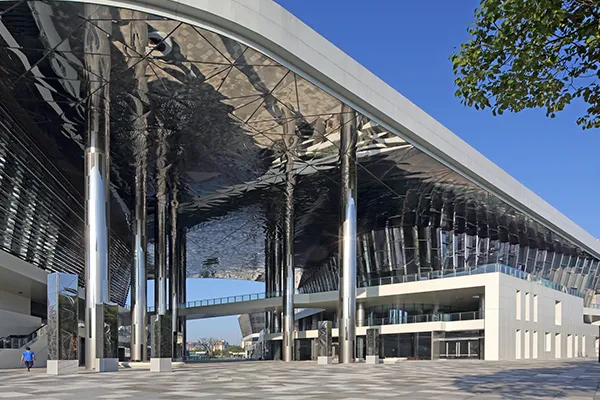

Applications courantes des bobines d'acier inoxydable

Construction & Architecture

Machinerie industrielle

Chimique & Pétrochimique

Préparation des aliments & Restauration

Automobile et transports

FAQ

La bobine d'acier inoxydable fait référence à une bande continue d'acier inoxydable enroulée en forme de bobine.. Il est couramment utilisé dans diverses industries pour des applications de fabrication telles que le formage de tôles., fabrication, et comme matière première pour une transformation ultérieure.

Les bobines en acier inoxydable possèdent plusieurs propriétés clés, y compris une résistance élevée à la corrosion, solidité et durabilité, résistance à la chaleur, hygiène et nettoyabilité, et attrait esthétique. Ils sont également connus pour leurs faibles exigences de maintenance et leur polyvalence dans divers processus de fabrication..

Les bobines d'acier inoxydable sont généralement fabriquées selon un processus appelé laminage à froid.. Il s'agit de faire passer une bande d'acier inoxydable à travers un ensemble de rouleaux pour réduire son épaisseur et lui donner la forme d'une bobine.. Le laminage à froid contribue à améliorer les propriétés mécaniques du matériau, Précision dimensionnelle, et finition de surface.

Oui, la bobine en acier inoxydable est hautement recyclable. À la fin de son cycle de vie ou lorsqu'il n'est plus nécessaire, la bobine d'acier inoxydable peut être collectée, traité, et recyclé. L'acier inoxydable conserve ses propriétés même après recyclage, et le processus peut être répété plusieurs fois sans dégradation significative de la qualité.