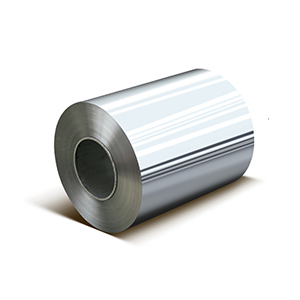

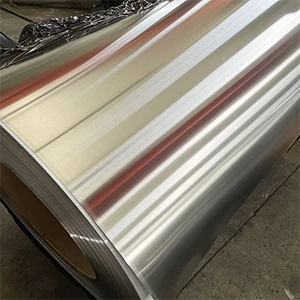

Катушка из нержавеющей стали

- Дом

- >

- Нержавеющая сталь

- >

- Катушка

Селективные катушки

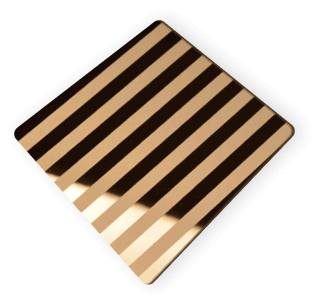

2Б

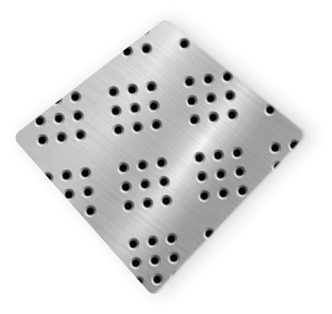

№1

бакалавр

8К

Доступная спецификация

| Информация о катушке из нержавеющей стали | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Техника | Чистота поверхности | Серия оценок | Толщина(мм) | Ширина(мм) | Заявление | |||||

| Основное измерение | ||||||||||

| 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 | |||||

| Горячекатаный | №1/2Е | 201/202/ 304 | 2.2-12.0 | Нефтехимическая промышленность Резервуары Строительный материал | ||||||

| Холоднокатаные | 2Б | 201/304 | 0.25-3.0 | |||||||

| 410S/430 | 0.25-2.0 | |||||||||

| №4 / Зеркало линии роста волос / Лен СБ | 201/304 | 0.22-3.0 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| бакалавр | 201/304 | 0.2-1.8 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| 2бакалавр | ||||||||||

| Химический состав и механические свойства рулонной нержавеющей стали | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Оценка | Химический состав (%) | Механическое исполнение | |||||||||

| С | А также | Мн | п | С | В | Кр | Мо | твердость | |||

| 201 | ≤0,15 | ≤1,00 | 5.5/7.5 | ≤0,060 | ≤0,030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241,HRB≤100, ВН≤240 | ||

| 304 | ≤0,08 | ≤1,00 | ≤2,0 | ≤0,045 | ≤0,03 | 8.0/11.0 | 18.00/20.00 | - | НВ≤187, ХРБ≤90, ХВ≤200 | ||

| 316 | ≤0,08 | ≤1,00 | ≤2,0 | ≤0,045 | ≤0,03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | НВ≤187, ХРБ≤90, ХВ≤200 | ||

| 316л | ≤0,03 | ≤1,00 | ≤2,0 | ≤0,045 | ≤0,03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | НВ≤187, ХРБ≤90, ХВ≤200 | ||

| 410 | ≤0,15 | ≤1,00 | ≤1,25 | ≤0,060 | ≤0,030 | ≤0,060 | 11.5/13.5 | - | НВ≤183, ХРБ≤88, ХВ≤200 | ||

| 430 | ≤0,12 | ≤1,00 | ≤1,25 | ≤0,040 | ≤0,03 | - | 16.00/18.00 | - | НВ≤183, ХРБ≤88, ХВ≤200 | ||

Значительное преимущество

Гибкий

Удобный

Типичные области применения

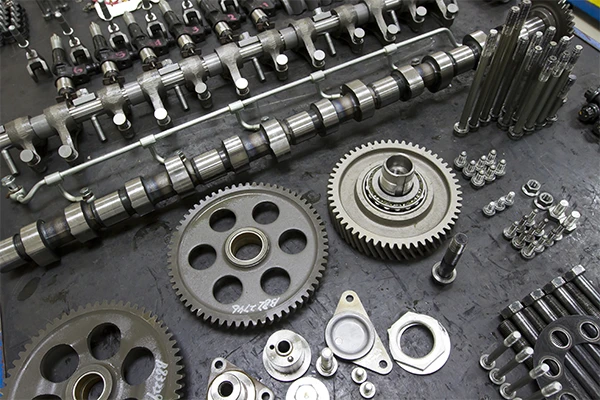

Промышленное оборудование

Электронное оборудование.

Кухонные принадлежности

Машины

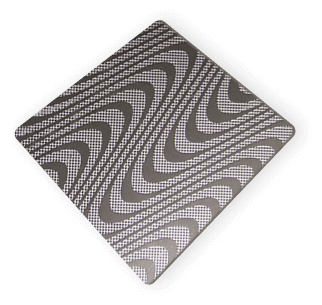

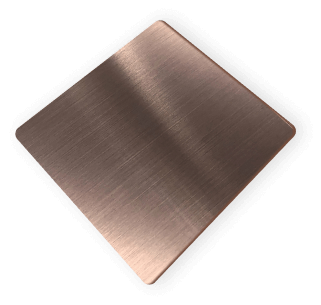

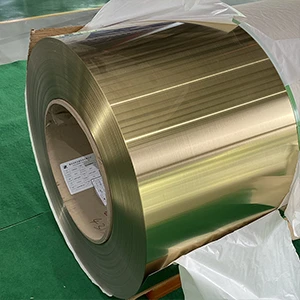

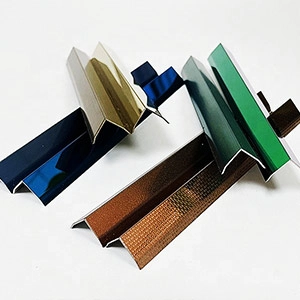

Матовый

Полированный

Цветной

Рельефный

сопутствующие товары

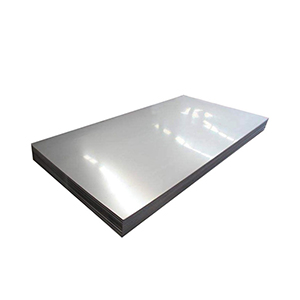

Лист

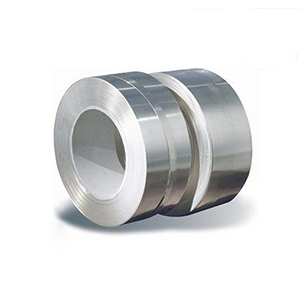

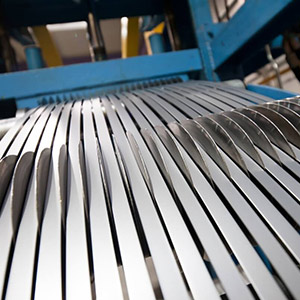

Полоска

Трубка

профиль

Готов начать свой проект по настройке?

Различные марки рулонов из нержавеющей стали

Оценка 201 является более дешевой альтернативой 304. Обеспечивает хорошую формуемость, умеренная коррозионная стойкость, и часто используется в приложениях, требующих эстетической привлекательности., например, посуда, тонет, и посуда.

Оценка 304 является наиболее распространенной и широко используемой маркой нержавеющей стали для рулонов.. Обеспечивает отличную коррозионную стойкость, хорошая формуемость, и подходит для различных применений в таких отраслях, как пищевая промышленность., химический, и архитектурный.

Оценка 316 известен своей превосходной коррозионной стойкостью по сравнению с 304. Содержит молибден, что повышает его устойчивость к химической коррозии, что делает его идеальным для использования в морской среде, фармацевтическое оборудование, и прибрежная архитектура.

Оценка 410 мартенситная нержавеющая сталь, известная своей высокой прочностью, твердость, и коррозионная стойкость. Он обладает хорошими механическими свойствами и может быть упрочнен термической обработкой.. Оценка 410 обычно используется в таких приложениях, как столовые приборы, стоматологические и хирургические инструменты, и клапаны.

Эта ферритная марка нержавеющей стали обеспечивает хорошую коррозионную стойкость и термостойкость.. Он обычно используется в таких приложениях, как автомобильная отделка., бытовая техника для дома, и архитектурные компоненты.

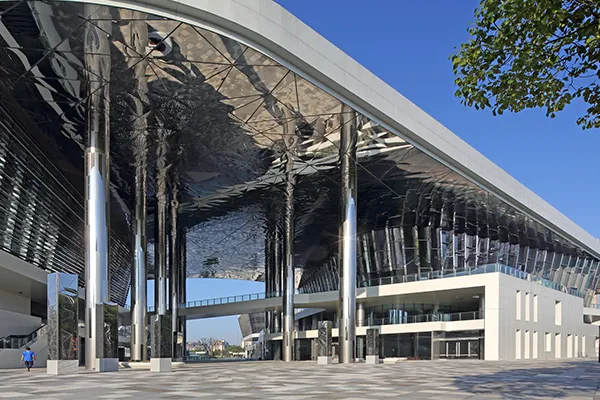

Общие применения рулонов из нержавеющей стали

Строительство & Архитектура

Промышленное оборудование

Химическая & нефтехимическая

Переработка пищевых продуктов & Кейтеринг

Автомобильная промышленность и транспорт

Часто задаваемые вопросы

Рулон из нержавеющей стали представляет собой непрерывную полосу нержавеющей стали, намотанную в форме катушки.. Он широко используется в различных отраслях промышленности для производственных задач, таких как формовка листового металла., изготовление, и как сырье для дальнейшей переработки.

Рулоны из нержавеющей стали обладают несколькими ключевыми свойствами., в том числе высокая коррозионная стойкость, прочность и долговечность, термостойкость, гигиеничность и возможность очистки, и эстетическая привлекательность. Они также известны своими низкими требованиями к техническому обслуживанию и универсальностью в различных производственных процессах..

Рулоны из нержавеющей стали обычно производятся с помощью процесса, известного как холодная прокатка.. Это включает в себя пропускание полосы нержавеющей стали через набор роликов, чтобы уменьшить ее толщину и придать ей форму рулона.. Холодная прокатка помогает улучшить механические свойства материала., точность размеров, и качество поверхности.

Да, катушка из нержавеющей стали легко перерабатывается. В конце жизненного цикла или когда он больше не нужен, катушку из нержавеющей стали можно собрать, обработанный, и переработано. Нержавеющая сталь сохраняет свои свойства даже после переработки., и процесс можно повторять несколько раз без существенного ухудшения качества..