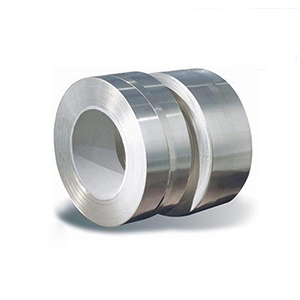

Полоса из нержавеющей стали

- Дом

- >

- Нержавеющая сталь

- >

- Полоска

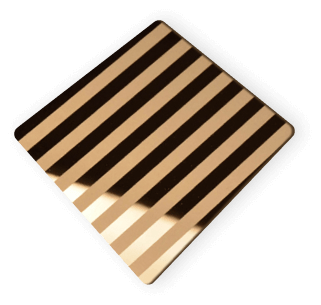

Селективные полоски

2Б

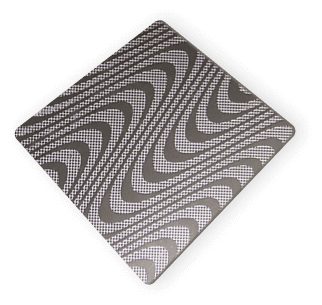

бакалавр

8К

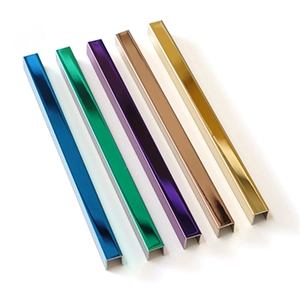

Цветной

Доступная спецификация

| Катушка из нержавеющей стали | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Техника | Чистота поверхности | Серия оценок | Толщина(мм) | Ширина(мм) | Заявление | |||||

| Основное измерение | ||||||||||

| 10- 600 | ||||||||||

| Горячекатаный | №1 / 2Д | 201 | 2.2-12.0 | Нефтехимическая промышленность,Резервуары Строительный материал | ||||||

| 304 | ||||||||||

| 410 | ||||||||||

| Холоднокатаные | 2Б | 201/304 | 0.25-3.0 | |||||||

| 410S/430 | 0.25-2.0 | |||||||||

| №4 / Волосы | 201/304 | 0.22-3.0 | ||||||||

| Зеркало / Шерсть | ||||||||||

| СБ | 410S/430 | 0.25-2.0 | ||||||||

| бакалавр | 201/304 | 0.2-1.8 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| 2бакалавр | ||||||||||

Значительное преимущество

Повышенная пластичность

Точная резка

Типичные области применения

Chemical & Food Processing

Трубная промышленность

Автомобильная промышленность

Аксессуары из нержавеющей стали

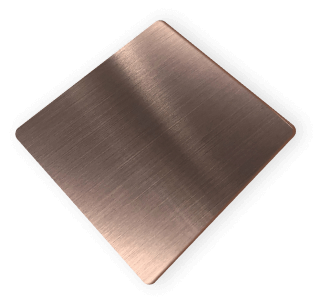

Матовый

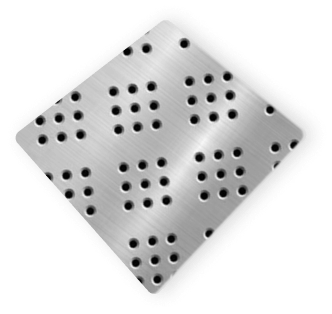

Полированный

Цветной

сопутствующие товары

Лист

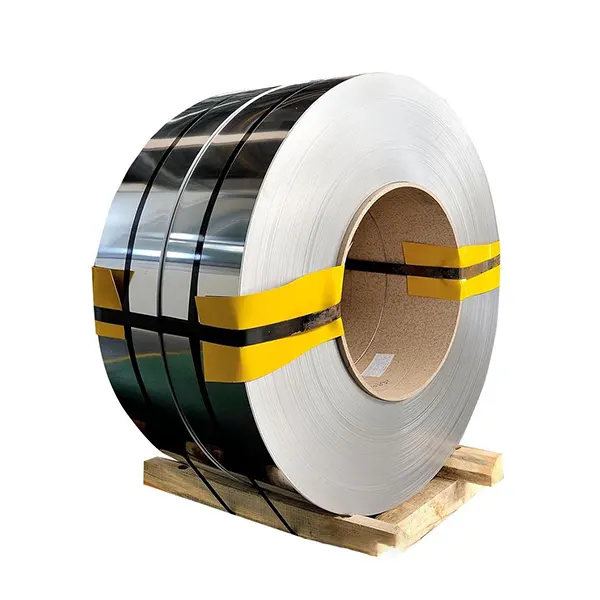

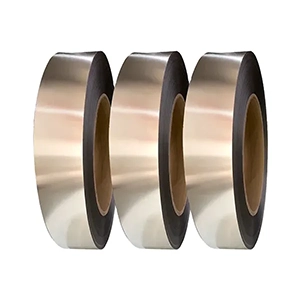

Катушка

Трубка

Профиль

Готов начать свой проект по настройке?

Что такое полоса из нержавеющей стали?

Полоса из нержавеющей стали представляет собой плоскую, узкий, и непрерывный металлический рулон из нержавеющей стали. Его производят посредством процесса, называемого холодная прокатка, где толщина листов или рулонов нержавеющей стали дополнительно уменьшается для достижения желаемых размеров.

Полоса из нержавеющей стали обычно имеет толщина начиная от 0.002 дюймы (0.05 мм) к 0.2 дюймы (5 мм) и ширина начиная от 0.2 дюймы (5 мм) к 12 дюймы (305 мм).

Общие применения рулонов из нержавеющей стали

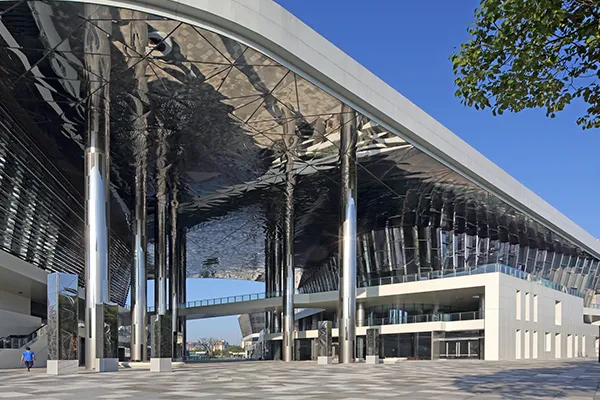

Строительная индустрия

Медицинские инструменты

Нефтяная и газовая промышленность

Автоматизированная индустрия

Кухонные приборы

Устойчива ли полоса из нержавеющей стали к коррозии?

Полоса из нержавеющей стали обладает высокой устойчивостью к коррозии., что делает его отличным выбором для различных приложений. Коррозионная стойкость полос из нержавеющей стали обусловлена, прежде всего, наличие хрома в его составе. Хром образует защитный слой на поверхности стали., известный как пассивная пленка или оксидный слой. Этот фильм действует как барьер, предотвращение попадания кислорода и влаги в основной металл, тем самым снижая риск коррозии.