source: Pinterest

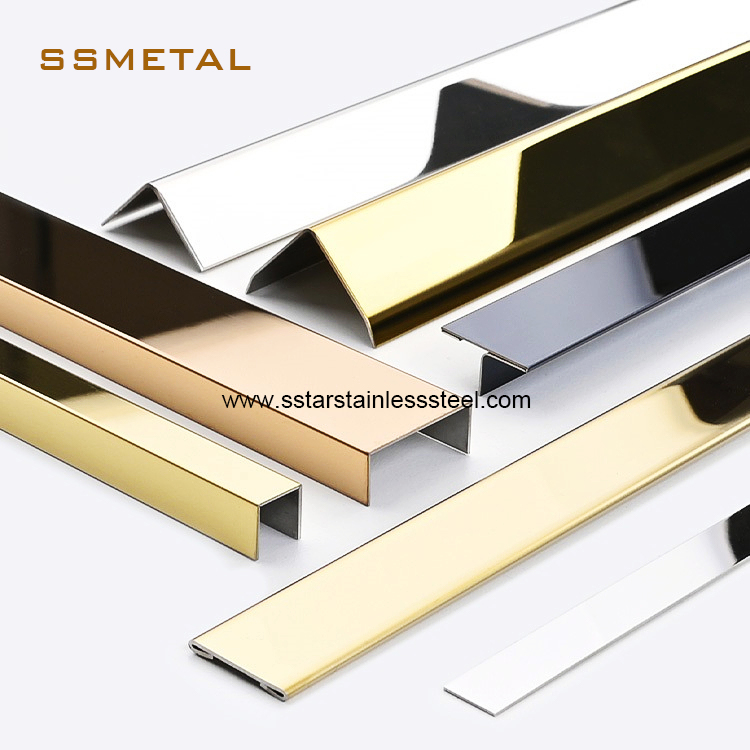

Stainless steel pipes are cylindrical tubes made of steel alloy containing a certain percentage of chromium. These pipes are widely used in different industries, including chemical, oil and gas, petrochemical, food processing and pharmaceutical, due to their excellent properties such as force, durabilité, and resistance to high temperatures and corrosion.

Choosing the right stainless steel pipe for a project is crucial to ensure the success and efficiency of the application. There are several factors to consider when selecting a stainless steel pipe, tel que type, noter, size, diameter, corrosion and temperature resistance, cost and quality.

Dans cet article, we will guide you through the different aspects of selecting a stainless steel pipe and help you make an informed decision. We will provide you with the necessary information to choose the right stainless steel pipe for your application or project. Donc, let’s dive in!

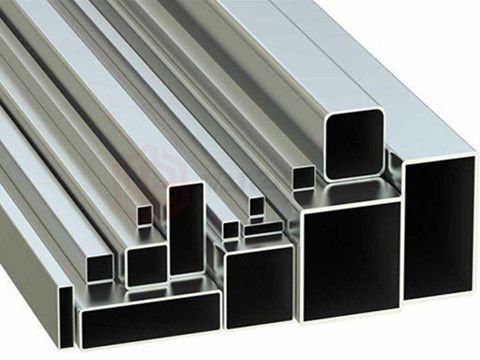

Types de tuyaux en acier inoxydable

source: Pinterest

Stainless steel pipes come in different types, y compris welded, seamless, and electric resistance welded (ERW).

- Welded stainless steel pipes are made by welding a strip of steel into a cylindrical shape. They come in different grades and sizes and are commonly used in applications requiring high pressure and large diameters.

- Seamless stainless steel pipes are made by piercing a solid cylindrical billet of steel. They have uniformity in their properties, high reliability, and are suitable for applications requiring high purity and high temperatures.

- Electric Resistance Welded (ERW) tuyaux en acier inoxydable are made by rolling a flat sheet of steel into a cylindrical shape and welding the edges together. They are commonly used in applications requiring small diameters and thinner walls.

Each type has its properties, avantages, et inconvénients, ce qui les rend adaptés à diverses applications.

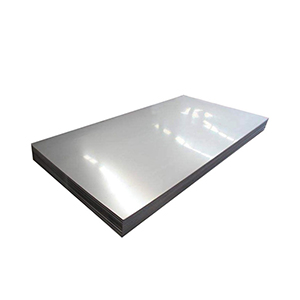

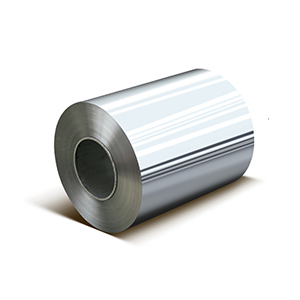

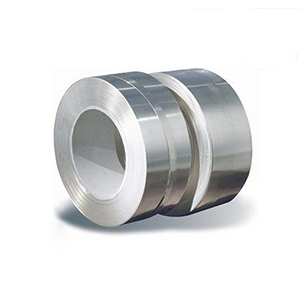

It is essential to source high-quality tôles et plaques en acier inoxydable, bobine, et strip from reputable manufacturers to ensure the manufacturing of high-quality stainless steel pipes.

Applications in Various Industries

source: Pinterest

Stainless steel pipes are widely used in various industries for the transportation due to their excellent properties.

In the industrie chimique, stainless steel pipes are used for the transportation of chemicals, acids, and bases. They are also used in the food and beverage industry for the transportation of fluids and gases, and in the oil and gas industry for the transportation of crude oil and natural gas.

Stainless steel pipes are also used in the pharmaceutical industry for the transportation of pharmaceutical products and in the construction industry for plumbing and structural applications.

Factors to Consider when Choosing

source: Pinterest

#1: Stainless Steel Pipe Grades

It is important to choose the right grade of stainless steel pipes. Stainless steel pipes are classified into four major grades: austénitique, ferritique, duplex, et martensitique. Each grade has unique properties, avantages, and disadvantages that make them suitable for different applications and environments.

Par exemple, austenitic stainless steel is highly corrosion-resistant, making it ideal for applications in aggressive environments, while ferritic stainless steel has good weldability and is often used in automotive applications.

Choosing the right grade of stainless steel pipe for a specific project or application depends on several factors. It is important to work with a reputable stainless steel supplier to ensure the proper selection of the stainless steel grade.

#2: Size and Diameter

The size and diameter of the stainless steel pipe are essential considerations in choosing the right pipe for a project. Factors such as pressure, flow rate, and fluid properties should be taken into account when determining the appropriate size and diameter.

Working with an experienced stainless steel manufacturer can help determine the suitable size and diameter for a particular application. They will ensure that the size and diameter of the stainless steel pipes are suitable for the project’s requirements.

#3: Résistance à la corrosion

Corrosion resistance is a critical property of stainless steel pipes, especially in industries that handle corrosive and aggressive substances. Factors such as the environment, pH, and temperature can affect corrosion resistance.

It is vital to understand the factors that affect corrosion resistance to choose the right grade of stainless steel pipe for a specific project or application. Sourcing high-quality stainless steel from reputable manufacturers is also essential in ensuring corrosion resistance.

#4: Résistance à la température

Temperature resistance is another essential property of stainless steel pipes. Different grades of stainless steel have varying temperature resistances, and the selection of the grade depends on the application’s required temperature range.

Working with a reputable stainless steel supplier or manufacturer can ensure that the grade of stainless steel pipe selected is suitable for the project’s specific temperature requirements.

#5: Coût

Cost is a significant consideration in selecting the right stainless steel pipe for a project. It is important to balance cost and quality to ensure that the stainless steel pipes are durable and reliable.

Factors that affect the cost of stainless steel pipes include the grade, size, and diameter. Working with a reputable stainless steel supplier or manufacturer can ensure that the cost of the stainless steel pipes is reasonable without compromising the quality.

#6: High-quality Materials

Choosing high-quality stainless steel materials from reputable manufacturers is essential when selecting stainless steel pipes.

Low-quality materials can affect the performance, lifespan, and safety of the pipes. It’s important to look into the chemical composition, manufacturing process, quality control, and testing practices of the materials before selecting them.

Reputable manufacturers have strict quality-control and testing practices and an experienced team to ensure consistent and high-quality products. Working with a good supplier ensures that the materials meet the required standards, specifications, and regulations, reducing maintenance and replacement costs and ensuring the durability, reliability and safety of the stainless steel pipes.

Conclusion

source: Pinterest

Choosing the right stainless steel pipe for a project depends on several factors. It is essential to work with a reputable stainless steel supplier or manufacturer to ensure the proper selection of the stainless steel pipe.

By sourcing high-quality stainless steel sheets and plates, bobine, and strip, and choosing the right supplier or manufacturer, you can ensure that the stainless steel pipes used in your project are durable, reliable, and meet the required standards and specifications.