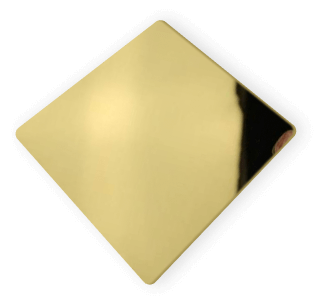

Stainless steel sheets and plates are widely used in various industries due to their excellent corrosion resistance, durability, and aesthetic appeal. Choosing the right size and thickness for these materials is crucial to ensure they meet the intended use and performance requirements. Whether you’re working on a construction project, designing a machine, or manufacturing a product, selecting the right stainless steel sheet or plate size and thickness is essential for achieving optimal results.

In this article, we’ll discuss factors to consider when choosing the right thickness for stainless steel plates, standard size options, and the importance of thickness tolerance. We’ll also cover related products such as stainless steel coils, strips, and pipes, as well as provide tips on how to choose a reliable stainless steel supplier.

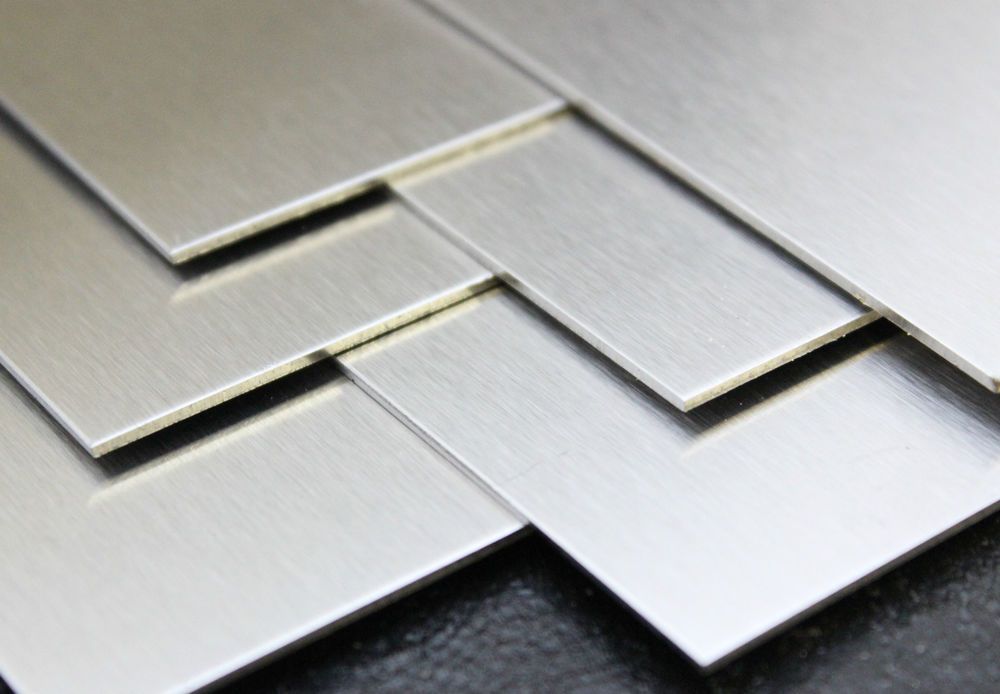

How to Choose the Right Thickness?

source: pinterest

When choosing the right thickness for stainless steel plates, it’s essential to consider several factors, such as the intended use, mechanical properties, and fabrication requirements.

Thicker plates provide better strength and stability, but also add more weight and cost. Thinner plates, on the other hand, are more flexible and lightweight but may compromise performance and durability. A good starting point for choosing the right thickness is to determine the application and the structural or design requirements.

Here’s a general guideline for the thickness options available, along with their common applications:

- 0.8 mm to 3.0 mm: suitable for decorative and artistic purposes, such as wall cladding and fabrication of sculptures, jewelry, and kitchen utensils.

- 3.0 mm to 12.5 mm: ideal for industrial applications such as construction, manufacturing, and mechanical engineering, where heavy-duty performance is essential.

- 12.5 mm and above: mostly used for extreme conditions such as offshore, marine, and mining industries, where safety and reliability are critical.

Additionally, it’s important to ensure that the thickness of the steel complies with local regulations and industry standards that dictate the minimum thickness required for food packaging.

What is the Thickness Tolerance?

source: pinterest

The thickness tolerance refers to the acceptable degree of variation in thickness that is considered to be within an acceptable range for steel food packaging. The thickness of steel used in food packaging is typically measured in millimeters or gauge, and it’s important to maintain a consistent thickness throughout the container to ensure that it provides adequate protection and meets industry standards.

Because steel manufacturing processes can result in slight variations in the thickness of the material, tolerance levels are established to ensure that the finished product meets the desired specifications. The thickness tolerance may vary depending on the specific application and industry, but generally, it ranges between +/- 5% to +/- 10% of the specified thickness.

Tolerance levels are established to account for the natural variation in the manufacturing process and ensure that the final product remains within the acceptable range of thickness. For example, by maintaining consistent thickness, steel food packaging can provide optimal protection and durability, ensuring that food products remain safe and of high quality throughout the distribution and storage process.

Different Size Options

source: pinterest

Stainless steel plates come in different sizes, with varying length, width, and thickness dimensions. The standard size options available on the market are typically in feet or meters, depending on the supplier’s location and operating standards.

Here’s an overview of the most common size options for stainless steel plates:

- Length: 2400 mm, 3000 mm, 6000 mm, and 8000 mm.

- Width: 1200 mm, 1250 mm, 1500 mm, and 2000 mm.

- Thickness: 0.8 mm to 50 mm.

Custom sizes for stainless steel plates are also possible, depending on the supplier’s capabilities and the customer’s specifications. It’s essential to check with the supplier for their custom size options and availability before placing an order.

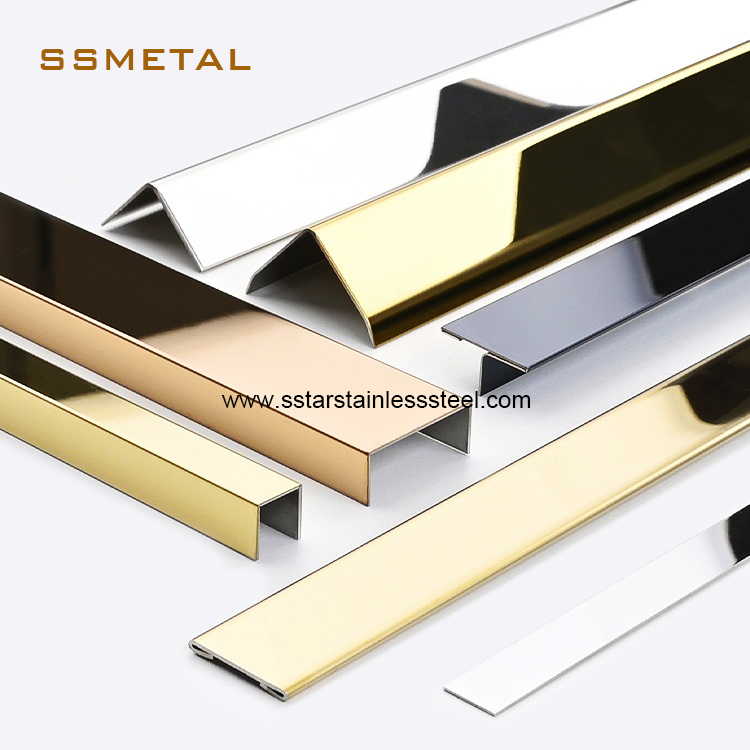

Common Applications

source: pinterest

Stainless steel sheets and plates are widely used in various industries due to their excellent properties and versatility.

Here are some of the most common applications for these materials:

- Construction: stainless steel plates are used for structural and cladding purposes in buildings, bridges, and other architectural structures.

- Kitchen appliances: stainless steel is commonly used in the manufacture of kitchen appliances and utensils due to its hygienic properties, corrosion resistance, and ease of cleaning.

- Medical and surgical equipment: Stainless steel’s non-porous surface and biocompatibility make it ideal for use in medical and surgical equipment, such as surgical implants and instruments.

- Food and beverage processing and packaging: stainless steel’s non-corrosive, hygienic properties and ease of cleaning make it a popular choice in the food and beverage processing and packaging industries.

- Oil and gas industry: Stainless steel is often used in the oil and gas industry due to its corrosion resistance and ability to withstand high-pressure, high-temperature environments.

- Automotive: stainless steel plates are used for parts and components such as exhaust systems, frames, and fuel tanks due to their heat and corrosion resistance.

- Chemical Processing: stainless steel plates are used for tanks, reactors, and piping systems due to their resistance to acids, alkalines, and other chemicals.

- Other Products: aside from stainless steel sheets and plates, other related products such as stainless steel coils, strips, and pipes are also widely used in various industries due to their excellent properties and versatility.

How to Choose a Stainless Steel Supplier

source: pinterest

Choosing a reliable and reputable stainless steel supplier is essential to ensure quality, availability, and customer service.

Here are some tips on how to choose a stainless steel supplier:

- Quality and reputation: the supplier should have a good reputation for supplying high-quality stainless steel products that meet industry standards.

- Pricing: while it is important to consider the cost of the stainless steel products, do not base your decision solely on pricing. Choose a supplier that offers a fair price for high-quality products and reliable services.

- Check for Certifications: a reliable supplier should have certifications such as ISO 9001 and other quality control systems to ensure their products meet the required standards.

- Experience: a supplier with considerable experience in the field can provide valuable insights and solutions to your specific situation.

- Delivery and lead times: check that the supplier can deliver the products you need on time, with reliable and fast shipping and handling services.

- Customer Reviews: checking online reviews and testimonials from previous customers can provide valuable feedback and insights into the supplier’s performance and reliability.

Conclusion

source: pinterest

Choosing the right size and thickness for stainless steel sheets and plates is critical for achieving optimal results in various applications. It’s essential to consider factors such as the intended use, mechanical properties, and fabrication requirements when selecting the right thickness.

Moreover, thickness tolerance is essential to maintain a consistent thickness throughout the entire plate. Standard size options for stainless steel plates are typically available, and custom sizes are possible, depending on the supplier’s capabilities.

Stainless steel sheets and plates are widely used in every aspect of life, such as kitchen appliances, medical equipment, architecture and construction and so on. Finally, choosing a reliable and reputable stainless steel supplier is essential to ensure quality and customer satisfaction.