source: pinterest

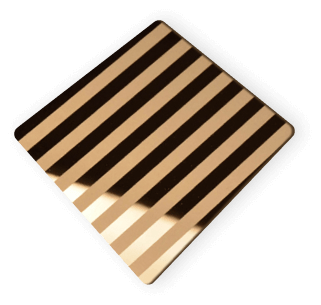

Stainless steel is an alloy of steel containing at least 10.5% chromium by mass, known for its resistance to corrosion and durability. It is a popular material used in different industries, such as construction, food service, medical equipment, and transportation, due to its aesthetically pleasing appearance and functionality.

Throughout this article, we will explore different questions pertaining to stainless steel grades, including the types of stainless steel available, the three most common grades of stainless steel, the differences between them, the grades of AISI stainless steel, and the various products offered by stainless steel manufacturers and suppliers. By the end of this article, you should have a better understanding of different grades of stainless steel and how they are used in various applications.

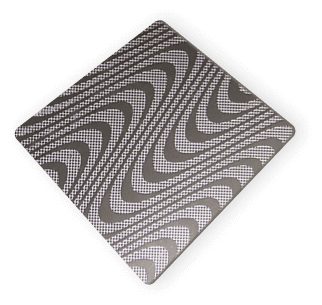

Types of Stainless Steel Grades

source: pinterest

Stainless steel is available in various types of grades, each with distinct properties and applications. These grades can be classified into five types, namely austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steels.

Austenitic Stainless Steel

Austenitic stainless steel is the most common type of stainless steel, accounting for around 70% of stainless steel production. It is non-magnetic and has excellent corrosion resistance, ductility, and toughness. Its primary use is in industries such as food processing, medical, and architectural.

Ferritic Stainless Steel

Ferritic stainless steel has a high percentage of chromium (10.5% to 30%), with low carbon content. It has lower corrosion resistance compared to austenitic stainless steel and is more affordable and easier to fabricate. Its primary uses are in the automotive industry, kitchenware, and building materials.

Martensitic Stainless Steel

Martensitic stainless steel is magnetic and hard, with high levels of carbon and chromium. It is used in automotive components, knife blades, and turbine blades due to its high strength and hardness.

Duplex Stainless Steel

Duplex stainless steel has a two-phase microstructure consisting of austenitic and ferritic structures. It offers high strength and corrosion resistance, making it suitable for chemical processing, oil and gas production, and pulp and paper production.

Precipitation-hardening Stainless Steel

Precipitation-hardening stainless steel contains alloying elements such as copper, aluminum, and titanium, which can be heat-treated to enhance its strength and hardness. It is used in aerospace components, high-performance engines, and surgical instruments.

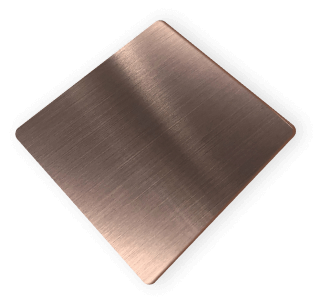

The Three Grades of Stainless Steel

source: pinterest

Understanding the different grades of stainless steel is important in choosing the right material for a specific application. Each grade has its unique properties, advantages, and disadvantages, making it essential to know which grade will work best for a specific use case. The three most common grades of stainless steel are 304, 316, and 420. Each grade has its unique properties and applications.

304 Stainless Steel

304 stainless steel is the most widely used grade of stainless steel, known for its excellent corrosion resistance and formability. It contains 18% chromium and 8% nickel, making it suitable for food processing, kitchen equipment, and chemical processing.

316 Stainless Steel

316 stainless steel is a higher grade of stainless steel than 304, containing 16% chromium, 10% nickel, and 2% molybdenum. Its higher molybdenum content enhances its resistance to corrosion, especially in chloride environments. It is ideal for marine applications, medical equipment, and chemical processing.

420 Stainless Steel

420 stainless steel is a martensitic stainless steel grade containing 13% chromium, providing good corrosion resistance and high hardness. It is suitable for blades, surgical instruments, and measuring tools.

When it comes to 304 vs 316 stainless steel, both grades are austenitic and have similar corrosion resistance properties. Nonetheless, 316 stainless steel is superior to 304 in chloride environments due to its higher molybdenum content. Additionally, 316 is more expensive than 304, so the choice between the two grades often depends on the specific application and budget.

Differences between the Grades of Stainless Steel

source: pinterest

The differences between stainless steel grades include their composition, mechanical properties, and costs. Knowing the differences is essential in choosing the right grade for specific applications. Factors such as corrosion resistance, strength, and hardness are essential in determining the best grade for specific uses. For example, austenitic grades are more corrosion-resistant, while martensitic grades are more durable and harder.

AISI Stainless Steel Grades

The American Iron and Steel Institute (AISI) classifies stainless steel into three categories based on their crystal structures: austenitic, ferritic, and martensitic.

- Austenitic grades: 200 (201, 202), 300 (303, 304, 316), and 400 (430) series

- Ferritic grades: 200 (201, 202), and 400 (409, 430) series

- Martensitic grades: 400 series (410, 420, 440)

Choosing the Right Grade of Stainless Steel

source: pinterest

Choosing the right grade of stainless steel is essential in ensuring the performance and durability of a particular product or application. Here are some factors to consider when selecting the appropriate grade of stainless steel:

- Corrosion Resistance: Consider the environment in which the stainless steel will be used. If it is going to be exposed to saltwater or other corrosive substances, a higher-grade stainless steel such as 316 or duplex stainless steel may be necessary.

- Strength and Hardness: Determine the level of strength and hardness required for the product or application. Different grades of stainless steel have different levels of strength and hardness, with martensitic stainless steel being the hardest and most durable.

- Fabrication: Consider the ease of fabrication and welding for the grade of stainless steel. Certain grades are more challenging to weld than others, resulting in increased welding costs and labor.

- Temperature Resistance: Determine the temperature range that the stainless steel will be exposed to. Some grades of stainless steel can handle higher temperatures better than others, making them suitable for high-temperature applications such as furnace components.

- Cost: Consider the cost of the grade of stainless steel. Higher-grade stainless steel is often more expensive than lower-grade, making it important to balance cost with performance requirements.

By taking these factors into account, you can choose the right grade of stainless steel that meets the specific needs of your product or application. It’s also essential to work with a reputable stainless steel manufacturer or supplier who can provide you with expert advice on selecting the right grade of stainless steel for your project.

Choosing the Right Stainless Steel Suppliers

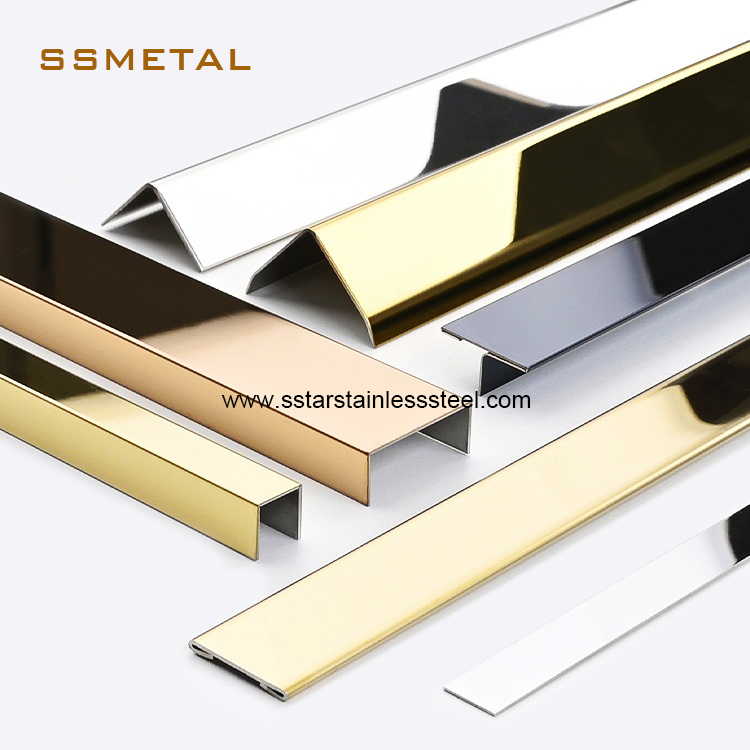

source: pinterest

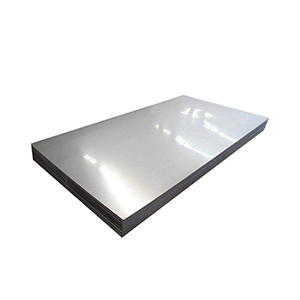

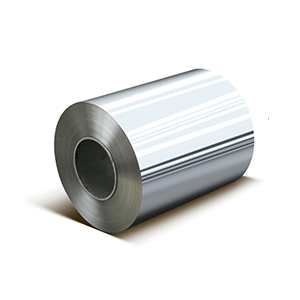

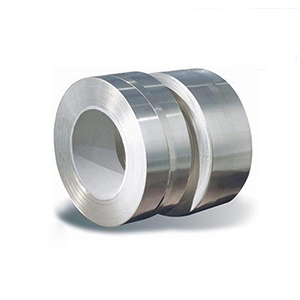

Choosing a reliable and reputable stainless steel manufacturer or supplier is crucial in getting the right grade and quality of stainless steel products. Manufacturers and suppliers offer different forms of stainless steel products, such as stainless steel sheets and plates, stainless steel coil, stainless steel strip, and stainless steel pipe.

Here are some factors to consider when choosing a stainless steel manufacturer or supplier:

- Experience and Reputation: Look for a manufacturer or supplier with years of experience in the industry and a good reputation for providing high-quality stainless steel products.

- Certifications: Check if the manufacturer or supplier has the necessary certifications such as ISO, ASTM, or EN to ensure that their products meet the required standards.

- Product Range: Look for a manufacturer or supplier who offers a diverse range of stainless steel products, including stainless steel sheets and plates, stainless steel coil, stainless steel strip, stainless steel pipe, and other custom-made products.

- Customer Support: A good manufacturer or supplier should provide excellent customer support, including technical assistance and after-sales support, to ensure that their clients are satisfied with their products and services.

- Pricing: Compare the pricing of different manufacturers or suppliers to get the best value for your money. However, remember that the cheapest option may not necessarily be the best option in terms of quality and service.

- Delivery and Shipping: Consider the manufacturer or supplier’s delivery time and shipping options to ensure that you receive your products in a timely and cost-effective manner.

By considering these factors, you can find a reliable and reputable stainless steel manufacturer or supplier who can provide you with high-quality products that meet your specific needs and requirements.

Conclusion

source: pinterest

Different grades of stainless steel have unique properties and advantages, making them suitable for various applications. Choosing the right grade of stainless steel depends on various factors such as corrosion resistance, strength, and hardness. A reliable and reputable stainless steel manufacturer or supplier is essential in getting the right products for specific applications.