Source: Pexels.com

As we talk about “aluminum” and “stainless steel”, the first thing that comes to mind should be pots, pans, and some other daily utensils. So before that, have we ever understood them and known what their differences are? Today, we will get to know them together.

What is Aluminium

Introduction

Aluminum is a metallic element that has a ductile nature. Aluminum is the most abundant metal element in the earth’s crust, ranking third after oxygen and silicon. It is very reactive chemically, so it is rarely found in its elemental state in nature. There are more than 250 kinds of minerals containing aluminum in total.

Aluminum compounds are widely distributed in nature, and as an important basic raw material for our national economic development, it is not only light in weight and of good texture, but also has fine ductility, electrical conductivity, thermal conductivity, heat resistance and nuclear radiation resistance.

Source: Pexels.com

Properties

Let’s take a look at the main properties of aluminum.

1. Lightweight.

Aluminum products or items made of aluminum are light in mass, which can save handling and processing costs. This feature can be used in the manufacture of aircraft, rail vehicles, automobiles, ships, bridges, high-rise buildings, and the lightest containers, etc.

2. Easy processing.

Aluminum has excellent ductility, easy to extrude hollow profiles with complex shapes, and is suitable for drawing processing and other cold thermoplastic forming. This characteristic can be used for the framework of the force structure parts, general supplies and various containers, optical instruments, and other complex shapes of precision parts.

3. Good corrosion resistance and weather resistance.

Many substances have no corrosive effect on aluminum & its aluminum alloys, owing to their ability to produce a hard and dense oxide coating on its surface. By choosing different alloys, they have excellent durability in industrial areas and coastal areas. This property can be used for door panels, vehicles, exterior coverings of ships, kitchen appliances, chemical installations, roof tiles, electric washing machines, desalination of seawater, packaging of chemical products, etc.

4. Chemical resistance.

It does not react to chemicals such as nitric acid, ice-cold acid, peroxide atmosphere, etc., and has great resistance to some other chemicals. This point has led to the use of aluminum in chemical devices, packaging and acids, and in the packaging of chemical products.

Source: Pixabay.com

Common Applications

Over the past fifty years, aluminum has become one of the most widely used metals in the world. Its usage has expanded as aluminum is an environmentally friendly material. The construction, transportation, and packaging fields, which account for about 60% of the total aluminum consumption for the year.

Construction field.

Due to the stability of aluminum in the air and its excellent appearance after anodic treatment, aluminum is increasingly used in the construction industry, especially in applications such as aluminum doors and windows, aluminum plastic tubes, decorative panels, and aluminum curtain walls.

Transportation field.

In order to reduce the weight of the transportation itself and reduce the pollution of the environment by exhaust gas emission, transportation tools such as motorcycles, all kinds of cars, trains, subways, airplanes, and boats begin to use aluminum & aluminum alloy as components and decorative parts in large quantities. As the hardness and strength of aluminum alloy processing materials continue to improve, the proportion used in the aerospace field starts to increase year by year.

Packaging field.

The usage of aluminum foil is expanding for various flexible packaging, all-aluminum cans, bottle caps, pharmaceutical packaging, and so on.

In other consumer areas, such as electrical and electronic, household appliances (refrigerators, air conditioners), and daily hardware, the amount of aluminum use and prospects are increasingly broad.

Source: Pixabay.com

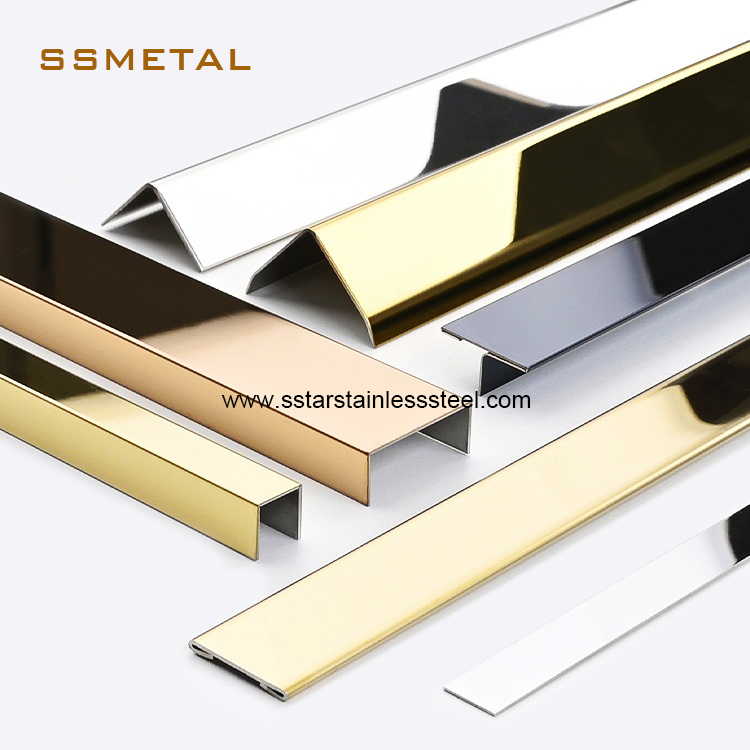

What is Stainless Steel

Introduction

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, and water as well as acid, alkali, salt, and other chemically leaching corrosive media, also known as stainless acid-resistant steel.

In reality, a steel resistant to weak corrosive media corrosion is often called stainless steel, and steel resistant to chemical media corrosion is called acid-resistant steel.

Due to the differences in the chemical composition of the two, the former is not necessarily resistant to chemical media corrosion, while the latter is generally stainless. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel.

Properties

Now take a look at the main properties of stainless steel.

1. Great weldability.

The requirements for welding performance will vary depending on the usage of the product. A class of tableware on welding performance is generally not required, even including some pot enterprises. But the vast majority of products require good welding performance of raw materials, such as second-class tableware, insulation cups, steel pipes, water heaters, and water dispensers, among others.

2. Corrosion resistance.

When the amount of chromium in steel atomic number of not less than 12.5%, can make a sudden change in the electrode potential of steel, rising from a negative potential to a positive electrode potential. It can stop electrochemical corrosion. The vast majority of stainless steel products require good corrosion resistance, like one or two types of tableware, kitchenware, water heaters, drinking fountains, etc.

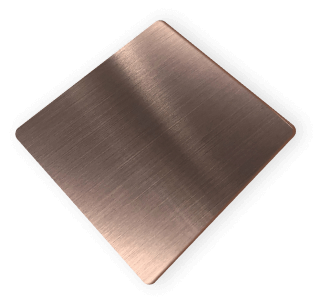

3. Polishing performance.

Stainless steel products in today’s society are generally polished in the production of this process, only a few products such as water heaters, water dispenser lining, do not need polishing. Therefore, it requires good polishing performance of stainless steel raw materials. This has also become the property of stainless steel products.

Source: Pixabay.com

Common Applications

As a highly versatile material, stainless steel is commonly used in the following fields in our daily life.

Construction field.

Most of the steel is used in the construction industry. Sustainable steel structures can be built quickly and at a low cost. Various forms and alloys of steel can be designed to meet the requirements of unique projects, allowing them to be integrated into all environments.

Transport field.

Engineering steels are forged steels that are designed for flexibility, strength, ductility, and corrosion resistance. They are used in general engineering and manufacturing applications but are mostly used in transportation vehicles.

Energy field.

All areas of the energy field, including nuclear energy, wind energy, electricity, and natural gas, all need stainless steel as infrastructure. Steel is also used for resource extraction, such as offshore platforms, earthmoving and quarrying equipment, cranes and forklifts, etc.

Packaging

Stainless steel packaging can be used to protect goods from water, air, and light, and is fully recyclable. This method of storage has existed for over 200 years.

Main Differences Between Aluminium & Stainless Steel

Source: Pixabay.com

Stainless steel vs aluminum, which is better? Let’s meet their difference and keep them in mind to make better choices in future daily life necessities.

1. Strength-to-weight ratio.

Aluminum is usually not as strong as steel, but it is also almost a third of its weight. This is the main reason why aircraft are made of aluminum.

2. Corrosion.

Stainless steel is composed of iron, chromium, nickel, manganese, and copper. Chromium is added as an agent to provide corrosion resistance. In addition, because it is non-porous, it increases corrosion resistance. Aluminum has high oxidation resistance and corrosion resistance, mainly due to its passivation layer. When aluminum is oxidized, its surface becomes white and sometimes pitted. In some extremely acidic or alkaline environments, aluminum may corrode rapidly and with catastrophic results.

3. Thermal conductivity.

Aluminum has much better thermal conductivity (heat conductor) than stainless steel. One of the main reasons it is used in automotive radiators and air conditioning units.

4. Cost.

Generally speaking, aluminum is usually cheaper than stainless steel.

5. Thermal properties.

Stainless steel can be used at much higher temperatures than aluminum, aluminum at about 400 degrees above will become very soft.

6. Electrical conductivity.

Compared with most metals, stainless steel is a very poor conductor, In contrast, aluminum is a very good conductor of electricity. Owing to its high electrical conductivity, lightweight, corrosion resistance, and other advantages, high-voltage overhead power lines are generally made of aluminum.

Cost: Aluminium vs. Stainless Steel

Source: Pixabay.com

Aluminum vs stainless steel cost, how to identify and choose? I believe there are many friends who have been, are now, or will be faced with this question, both of them are excellent metal materials, and both are often used in construction, decoration, and other industries and fields. So how to choose them in order to maximize the benefits? Now let’s take a look at the cost characteristics of these two materials!

1. Price.

Usually down to say, the price of stainless steel is more expensive than aluminum, partly due to the impact of the market, and partly due to cost issues.

2. Heat conductivity.

In terms of thermal conductivity, aluminum has better thermal conductivity than stainless steel, which is also one of the main reasons why aluminum plates are commonly used in automobile radiators and air conditioning units.

3. Usability.

In the usability, aluminum is quite soft, easy to cut and shape, and due to high resistance to wear and tear, stainless steel may be difficult to use, and stainless steel hardness is also greater than aluminum, compared to aluminum more difficult to shape.

4. Electrical conductivity.

Stainless steel has poor electrical conductivity, while the aluminum sheet is a better material for electric power. It is often used in the manufacture of high-voltage overhead power lines thanks to its high electrical conductivity, lightweight, and corrosion resistance.

The points above explain the higher cost of stainless steel than aluminum. So how to choose? You can choose the material according to the current use of different scenarios, the need for high strength plate can be selected from stainless steel, and if it is the need for lightweight, the requirements of shaping, the need for more profile patterns, aluminum will be a more suitable choice.

Choosing Cookware: Aluminium or Stainless Steel

Source: Pixabay.com

Aluminum Cookware

Strong Points

1. Excellent thermal conductivity.

When comparing aluminum and steel for cooking food quickly and evenly, the difference between them is still some distance apart. Why? Aluminum is up to 15 times more effective than stainless steel at dissipating heat faster and more freely. This reduces hot spots, allowing you to create less sticky food faster.

2. No sticking and easy to clean (when hard anodized and/or non-stick coated).

Uncoated hard anodized aluminum cookware has a non-stick surface that is much easier to clean than steel. It also contains no non-stick chemicals. However, non-stick-coated aluminum is by far the easiest to use and clean. You can cook sticky foods with little or no oil.

3. Non-reactive, not change the flavor (when hard anodized and/or non-stick coated).

Hard anodized aluminum cookware will not chemically react with acidic foods. You can cook as you like without leaching metallic flavors into your meals. However, you must be careful not to damage the non-stick coating or anodized layer. Doing so may expose the active bare aluminum.

Source: Pixabay.com

Drawbacks

1. Bare aluminum reacts with acidic foods (from untreated aluminum or scratched hard anodized bare cores).

Acidic foods (tomatoes, citrus, onions, etc.) can cause bare aluminum to react and leach into your meals. Now, unless you have kidney disease, aluminum cookware poses no real health risk. However, it can ruin the taste of your food and the appearance of your cookware.

2. Not for high temperatures or ovens (medium heat only).

Aluminum melts at a relatively low temperature of 1,221 degrees Fahrenheit and loses half its strength at 600 degrees Fahrenheit. Excessive heat will weaken, discolor and warp aluminum cookware, including hard anodized finishes. Non-stick-coated aluminum has the highest heat limit. Once it exceeds 464°F, it will emit harmful fumes.

3. Not to use metal utensils.

Metal utensils can easily scrape untreated aluminum and damage the non-stick coating. Uncoated hard anodized aluminum cookware holds up better to metal, but deep scratches can expose reactive aluminum. Use only wood or silicone utensils.

Source: Pixabay.com

Stain steel Cookware

Strong Points

1. Ideal for high-temperature cooking, searing and browning.

Stainless steel is three times denser than aluminum. So, while it takes longer to heat up, once it gets hot, it stays hot. When you put cold food on hot steel, the temperature does not fluctuate as much as aluminum.

2. Durable metal utensils, and safe cookware surfaces.

Because of its higher density, stainless steel products are more resistant than aluminum against damage on their surface, without having to worry about its anodized layer or coating. Therefore, you can use abrasive cleaners for food that sticks to it without causing terminal damage.

3. Nonreactivity and corrosion resistance.

Stainless steel does not react chemically with acidic foods. So, no matter what the ingredients are, the taste of the food remains unchanged! It is suitable for anything from hearty steaks to acidic tomato or lemon dishes.

4. Attractive surface.

Decorative stainless steel now can be found everywhere, no matter the decor, stainless steel’s sleek, stylish finish looks great in any kitchen. So, matching it to your home will never be a problem.

Source: Pixabay.com

Drawbacks

1. Cookware is more difficult to clean.

Using stainless steel to cook delicate foods without sticking can be a challenge. Even non-stick foods can stick without proper heating and oiling. Now, it’s relatively easy to prevent sticking with stainless steel, but it’s more difficult than aluminum.

2. May be expensive.

One of the main disadvantages of stainless steel is its high upfront cost. Now, you can find cheap sets, but they may only have a single layer of steel and not be of great quality. The full package is more expensive, but a good set can easily last a lifetime and is a wise investment. And the stainless steel manufacturer often sells as a complete set.

3. Can stain or lose its luster.

Stainless steel can be discolored by hard water, burning food, and chlorine-based cleaners. But this is easily prevented, use mild cleaners and avoid using too much heat.

Conclusion

Source: Pixabay.com

To sum up, today we have approached aluminum and stainless steel and learned about their characteristics and differences, and daily usage. When it comes to choosing cookware, we need to practice a pair of keen eyes to identify different cookwares. And no matter what materials you buy, you should buy guaranteed brand products through proper channels and ask for invoices, and warranty cards, as a basis for future maintenance.