Source:Pixabay.com

Stainless steel is a common and very useful material in our lives. It is used for water heaters in our bathrooms, cutlery in our kitchens, washing machines, refrigerators and much more area. The number of stainless steel supplier is also increasing nowadays. Do you know much about this metal material?Let’s learn more about it today.

What is Stainless Steel?

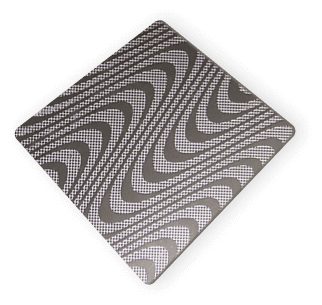

Stainless steel with stainless and corrosion resistance as its main characteristic, moreover it is a steel with a chromium content of at least 10.5% and a maximum carbon content of no more than 1.2%. It is an alloy of iron and several other elements (such as nickel, chromium, molybdenum and carbon) and is therefore more resistant to corrosion than ordinary iron or steel (simple iron and carbon).

These stainless steel elements, such as nickel, chromium and other additives, give it a passivated oxide layer that prevents rusting and creates a shiny, reflective surface. Compared to ordinary steel, the glossy surface of stainless steel is harder to lose its lustre, hence the name “stainless steel”.

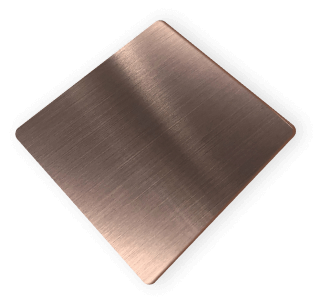

Due to its high chromium content, stainless steel is resistant to corrosion. It is resistant to many chemicals and oxidisers, including water, gases and acids. It is also stronger than many other metallic materials and is resistant to wear. It can withstand high temperatures and pressures and does not deform or wear easily.

As stainless steel has good corrosion resistance, it can resist corrosion, high temperatures, low temperatures and wear resistance and can be used to manufacture high quality products, hence it can be 100% recyclable material with a relatively high value for use.

Source:Pixabay.com

How is Stainless Steel Recycled?

Stainless steel recycling mainly has two aspects of industry and life.

In the industrial scrap stainless steel, there are mainly stainless steel welded pipes for urban landscape projects. And for automotive industry, there is mainly ferritic stainless steel for automotive exhaust pipes. Other industries, such as urban water supply projects, environmental protection, petrochemical and electric power industries, also have a large amount of stainless steel scrap produced. Edgings (new materials) are cut and stamped down in the industrial production process. It includes some tubes, rods and plates that can be used directly but not in large quantities. Pumps and containers for oil, gas and acid are a large market for a large number of scrap stainless steel tanks, pipes, pumps and valves.

In life scrap stainless steel, end-of-life stainless steel appliances used in daily time can be recycled, such as kitchen equipment and cutlery. China’s annual imports of scrap stainless steel from Japan and South Korea are mostly of this type. After the stainless steel has been scrapped it can only be returned to the furnace for using as furnace charge. Food processing industry mainly manufactures food processing machinery and containers, such as grain, beer and beverage, dairy processing equipment, frozen refrigeration equipment, etc., which can also be recycled.

The main recycling method for scrap stainless steel recycling is melting and casting into raw steel ingots. The metal itself does not lose strength in repeated recycling. However, problems can arise when recycling tinplate and galvanised drums. Only small quantities of tin and galvanised barrels are currently recycled directly into furnaces, as small amounts of tin or zinc, even below 0.01%, can form hardening in the steel, making subsequent rolling difficult.

We also use recycled old stainless steel to manufacture more other stainless steel product. Some companies use stamping and other methods to manufacture the products. In this recycling process, the waste bars must be cleaned and stripped of paint. Besides, attention should be paid to the treatment of the three wastes to reduce environmental pollution.

Source:Pixabay.com

Benefits of Recycling Stainless Steel

Scrap stainless steel recycling is the secondary raw material. The recycling of secondary materials can save material consumption and reduce costs.

Furthermore it reduces the energy consumption in the production process and also reduces the pollution of the environment. Through the recycling and use of such waste materials, we can save resources for the country, purifying the environment, turning waste into treasure, protecting natural resources, reducing waste and benefiting the country and the people.

The recycling of scrap stainless steel also has a high economic value, in terms of making it easier to collect and dispose of material that makes money for recycling companies and stainless steel suppliers. Its recycling creates more jobs and contributes to economic growth in the disposal and recycling process as well as in various industry sectors.

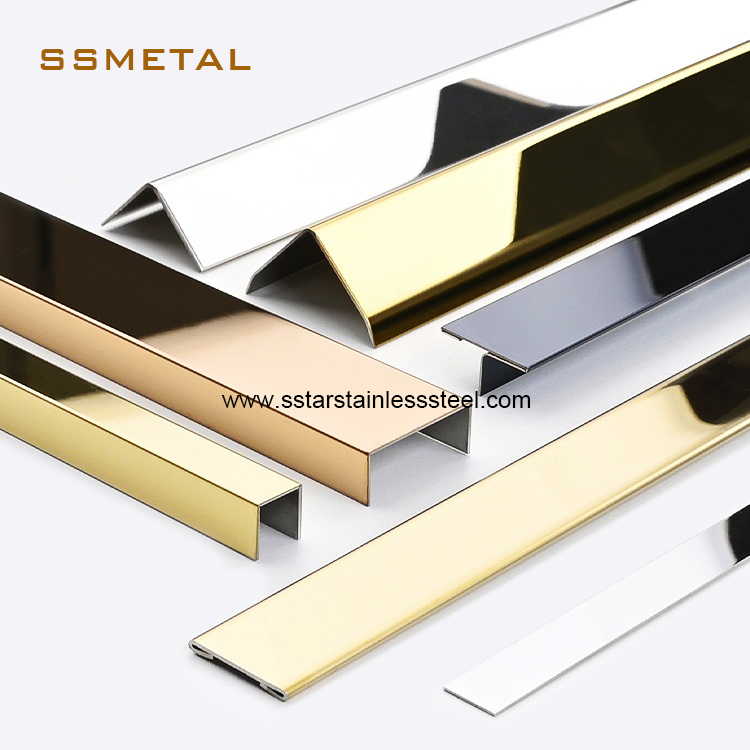

Source:Pixabay.com

Applications of Recycled Stainless Steel

The environmental benefits of using highly recycled materials have been recognised by the US and Canadian Green Building Council, who have given their approval to the use of these materials. Stainless steel can be 100% recycled into the same product with no reduction in quality.

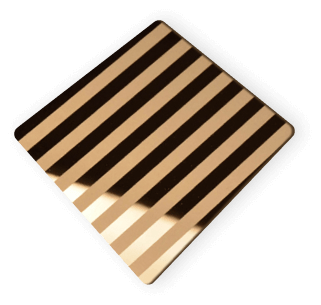

Building and Construction Materials

This was one of the first areas where stainless steel was used. In architectural decoration, stainless steel was then mainly used for surface decoration and cladding of components such as external walls, internal and external columns, handrails, floors, lift wall panels, doors, windows and curtain walls in high-rise buildings. The stainless steel sheet has been surface treated, coloured, plated and anti-fingerprint treated, which solves the problem of easy handprints after touching, so that the application of stainless steel is further expanded.

Kitchen and Household Appliances

The appliance industry uses a large amount of stainless steel, including automatic washing machine liners, water heater liners, microwave ovens and electric oven casings, refrigerator liners. The domestic appliance industry is currently a potentially large market for stainless steel applications. Microwave ovens, refrigerators, air conditioners and televisions produced in China have been competitive export commodities in the world.

Medical Equipment and Devices

Stainless steel is commonly used in the manufacture of surgical instruments such as scalpels, forceps and clamps because of its high strength, resistance to corrosion and ability to retain sharp edges. It is also used in the production of dental and orthopaedic implants. Moreover, it can be used in the production of various medical devices such as hospital beds, wheelchairs and examination tables.

Stainless steel plays a vital role in the production of medical devices and their components. It provides the strength, durability and corrosion resistance required for equipment that must operate reliably and safely in demanding medical environments.

Automotive and Transportation Components

This is currently the fastest growing application area for stainless steel. The choice of high-strength stainless steel for vehicle body solutions can significantly reduce the weight of the vehicle, increase the strength of the body side and reduce maintenance costs by using stainless steel for vehicle panels and decorative components. In addition, stainless steel can also be used in the exhaust system of vehicles because of its resistance to chloride ion corrosion and heat resistance.

Source:Pixabay.com

Challenges and Limitations

The stainless steel industry still has to deal with a number of challenges and limitations. There is a serious shortage of raw material resources for stainless steel such as nickel and chromium, and a shortage of stainless steel scrap resources with a low utilisation rate.

Not only is the industry competition further intensified, but also the product features are not outstanding. There is also the imperfect construction of the downstream industry chain, the survival of enterprises and stainless steel sheet supplier will face great challenges.

Environmental pollution from recycling is mainly generated by transportation and stacking of solid waste, water pollution and noise pollution during processing, air pollution during smelting, etc. With the increase in end-of-life, it is important to regulate how industrial waste such as stainless steel strip oil is handled.

The limited collection and treatment infrastructure in some areas makes it difficult to ensure a safe and pollution-free production and recycling process, as well as to sort and identify different types of stainless steel. This can affect the normal operation and production of stainless steel scrap collection sites. Formal, qualified sites will grow in size, while smaller, heavily contaminated sites are likely to be closed.

Source:Pixabay.com

Future

Recycling steel scrap resources not only saves energy and reduces emissions, but is also more environmentally friendly. It improves the utilisation rate of steel scrap, which can effectively solve the problem of excess steel scrap resources, and can be considered a hundred times more beneficial than harmful. Today, recycling technology and processing methods have been further enhanced and improved. The recycling rate of the material has been maximised.

Manufacturers and consumers of demand and adoption continue to increase, and now stainless steel supplier as a major consumer of steel scrap, the scrap purchased from the material type, specifications and the strict degree of inspection, have undergone considerable changes. The use of steel scrap is gradually moving in a positive direction.

Stainless steel mills are raising the bar on scrap inspection. And the Ministry of Industry and Information Technology has made requirements for the access of scrap steel processing enterprises. These are more perfect scrap steel processing and recycling, processing and distribution system, for the steel industry to use more scrap steel, to further achieve green development and build green channel to make efforts.

The relevant departments pointed out, that steel recycling and processing enterprises should recycle and process as much steel scrap as possible , to achieve a light to heavy program, more quality and quantity for steel enterprises to provide steel scrap resources. It will lead to a more honest and reliable relationship with steel enterprises, and a win-win industrial chain cooperation between supply and demand.

Source:Pixabay.com

Conclusion

In summary, steel scrap, as an infinitely recyclable material resource, has high economic, environmental and social benefits. Nowadays the recyclable steel scrap industry has huge room for development, and also with very promising development trend.