Source: Good Housekeeping

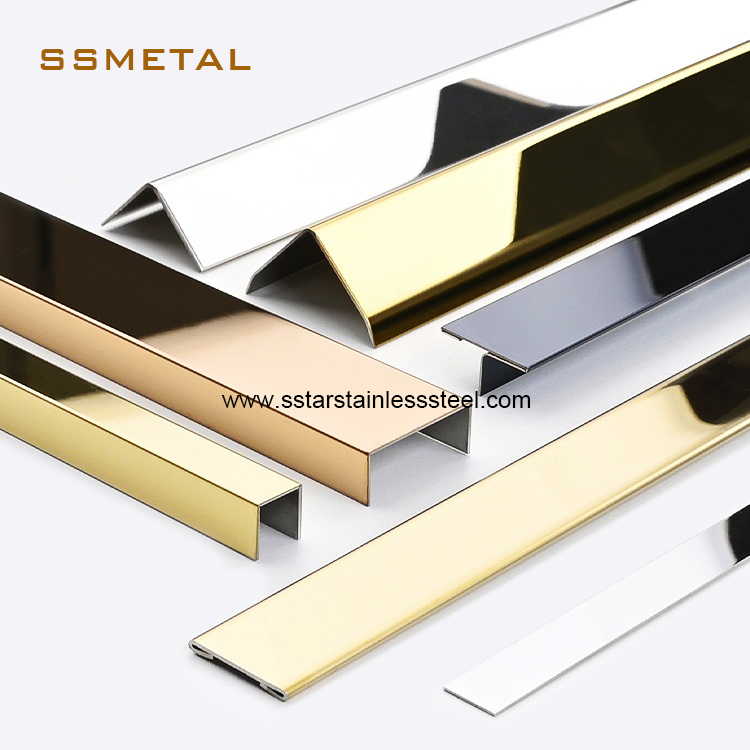

Stainless steel is widely used in food processing facilities, medical facilities, and other industrial settings due to its durability, resistance to corrosion, and low maintenance. However, stainless steel equipment still requires regular cleaning and maintenance to ensure it remains in good working condition and continues to meet industry standards for cleanliness. How to properly clean and maintain stainless steel products is a very important issue.

Why Needs Cleaning and Maintenance?

Source: LinkedIn

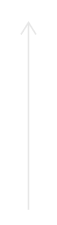

Stainless steel equipment can become contaminated with bacteria, viruses, and other harmful substances if it is not properly cleaned and maintained. This can pose a serious health risk to workers and customers who come into contact with the equipment. When it is is exposed to various environmental factors such as moisture, dirt, and chemicals, which can cause rust, corrosion, and staining.

Proper cleaning and maintenance are necessary to prevent these issues and extend the life of the equipment. Additionally, failing to clean and maintain stainless steel equipment can lead to rust buildup, discoloration, and other forms of damage that can compromise the integrity of the equipment and eventually render it unusable. Regular cleaning also helps to maintain the appearance of the equipment, making it look new and shiny.

How to Clean and Maintain?

Source: Kitchn

Cleaning and maintaining stainless steel equipment involves three main techniques: hand-washing, chemical cleaning, and steam cleaning. Hand-washing involves using warm water and a mild detergent to scrub the surface of the equipment with a soft cloth or sponge. Chemical cleaning involves using specialized cleaning products that are designed to dissolve grease, oil, and other contaminants on the surface of stainless steel equipment. Steam cleaning involves using high-pressure steam to remove dirt and grime from hard-to-reach areas.

Cleaning Techniques

Source: Fortador

Hand-washing is the most common and easiest way to clean stainless steel equipment. When hand-washing stainless steel equipment, it’s important to use a mild detergent that is free from abrasive materials. Scrub the surface gently with a soft cloth or sponge, working in circular motions to remove any dirt or grime. Avoid using abrasive cleaners or scouring pads as they can scratch the surface of the equipment. After washing, rinse the equipment thoroughly with water and dry with a clean, dry cloth.

Chemical cleaning is more effective than hand-washing and is ideal for removing tough stains and buildups. However, it is important to use the right chemicals as some can damage the surface of the equipment. Chemical cleaning should only be done by trained professionals who understand how to safely handle and apply cleaning products. Always follow the manufacturer’s instructions when choosing and using chemical cleaners. Apply the cleaner to the equipment and let it sit for the recommended time, then rinse thoroughly with water and dry with a clean, dry cloth.

Steam cleaning is the most effective way to remove bacteria and other contaminants from stainless steel equipment, particularly in hard-to-reach areas. It is also eco-friendly as it does not require the use of chemicals. However, steam cleaning equipment can be expensive and requires professional installation. If you plan to use steam cleaning, make sure to follow the manufacturer’s instructions and use the equipment properly. However, it should only be done by trained professionals who understand how to safely operate steam cleaning equipment.

Dos and Don’ts of Cleaning Stainless Steel Equipment

Source: Fortador

There are several do’s and don’ts to remember when cleaning stainless steel equipment. Always use a mild detergent when hand washing stainless steel equipment, and follow the manufacturer’s instructions when using chemical cleaning products. Additionally, stainless steel equipment needs to be cleaned regularly to prevent buildup and staining. When handling cleaning products, always wear protective gloves and glasses and hand wash with warm water, mild soap and a soft cloth or sponge.

Moreover, a protective coating can be applied to stainless steel equipment to prevent rusting. However, do not use abrasive cleaners or scouring pads on stainless steel equipment and do not allow harsh chemicals to remain on the surface for too long, and do not use the wrong equipment or techniques when cleaning stainless steel equipment. Even more so, do not use the wrong equipment or techniques, such as using wire brushes or steel wool.

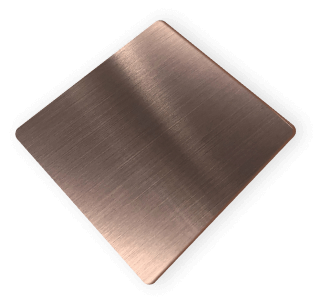

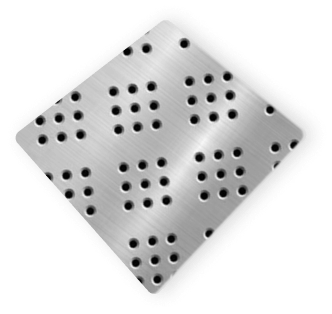

Applying Protective Coatings to Prevent Rust Buildup

Source: The Piping Mart

To prevent rust buildup on stainless steel equipment, it is important to apply a protective coating that prevents moisture from coming into contact with the equipment surface. Applying a protective coating to stainless steel equipment is an effective way to prevent rust buildup and extend the life of the equipment.

There are several different types of protective coatings available, including acrylic coatings, epoxy coatings and polyurethane coatings. The correct type of coating should be selected for the specific stainless steel equipment and the manufacturer’s instructions should be followed when applying the coating. It is likely that different stainless steel suppliers and stainless steel sheet suppliers will have different suitable coatings.

Common Mistakes to Avoid

Source: Reliance Foundry

To avoid damaging your stainless steel equipment, here are some common mistakes to avoid:

Using Abrasive Cleaners and Scouring Pads

Source: Alibaba

One of the biggest mistakes is using abrasive cleaners or scouring pads. Abrasive cleaners and scouring pads can scratch the surface of the equipment, causing damage that cannot be repaired and compromise its integrity.

Instead, it’s recommended to use soft cloths or non-abrasive sponges when cleaning stainless steel equipment. Microfiber cloths are an excellent choice, as they are gentle on the surface but still effective at removing dirt and grime. It’s also important to pay attention to the direction of the grain on the stainless steel surface when cleaning. Cleaning against the grain can cause scratches and damage, so it’s best to move in the same direction as the grain.

Leaving Harsh Chemicals on the Surface for Too Long

Source: Clean Plus

Another mistake is leaving harsh chemicals on the surface for too long. Harsh chemicals such as bleach or ammonia can cause staining and discoloration of the stainless steel, especially if they contain high levels of minerals or chlorine. In addition to causing aesthetic damage, harsh chemicals can also damage the surface of the equipment if left on for too long, compromising its integrity and potentially leading to rust or corrosion.

To avoid this problem, it’s important to always follow the manufacturer’s instructions when using chemical cleaners. Be sure to apply the cleaner only as directed, and rinse the surface thoroughly with water as soon as the cleaning process is complete. This will help ensure that no residual chemicals are left on the surface of the equipment, reducing the risk of staining, discoloration, or damage.

Using the Wrong Equipment and Technique

Source: Squeaky Green

Finally, using the wrong equipment or technique when cleaning stainless steel equipment can also lead to damage and compromise the integrity of the equipment. Using the wrong equipment and technique such as using a wire brush or steel wool can damage the equipment and cause scratches. This not only compromises the appearance of the equipment but can also make it more susceptible to further damage.

Conclusion

Source: Compact Appliance

Maintaining stainless steel equipment with proper cleaning and maintenance is essential for ensuring its longevity and preventing contamination in industrial settings. By following proper cleaning techniques, avoiding common mistakes, and applying protective coatings as needed, you can ensure that your stainless steel equipment remains in good working condition and meets industry standards for cleanliness. Remember to use the right cleaning products, avoid common mistakes, and apply protective coatings to prevent rust buildup. With proper care, your stainless steel equipment will look new and shiny for years to come.