Source: https://expertworldtravel.com

Le titane et l'acier inoxydable sont tous deux des matériaux de haute qualité largement utilisés dans diverses industries. Ils présentent tous les deux d'excellentes performances dans des domaines tels que force, résistance à la corrosion, et d'autres aspects. Cependant, Lors du choix entre ces deux matériaux, Nous devons considérer de nombreux facteurs, y compris le coût, ductilité, difficulté de traitement, et d'autres facteurs. La comparaison entre le titane et l'acier inoxydable est devenu un sujet brûlant dans de nombreux domaines industriels. Cet article se plongera dans leurs similitudes et leurs différences, Vous aider à mieux comprendre comment choisir le matériel le plus approprié pour différentes occasions.

Qu'est-ce que le titane?

Source: https://testoil.com

Le titane est un élément chimique avec le symbole Ti et le nombre atomique 22. C'est un métal de transition brillant avec une couleur argentée, basse densité, et haute résistance. Le titane est connu pour son excellente résistance à la corrosion, Et c'est aussi biocompatible, En faire un matériau idéal pour une utilisation dans les implants médicaux.

En plus de son utilisation en médecine, Le titane est largement utilisé dans diverses industries, comme l'aérospatiale, automobile, et construction, En raison de sa force, basse densité, et résistance à des températures élevées. Il est également utilisé pour créer des alliages haute performance qui résistent aux environnements extrêmes, comme l'eau de mer ou les environnements acides.

Types de titane

Source: https://www.top-mi.com

Il existe plusieurs types d'alliages de titane, chacun avec ses propres propriétés et utilisations uniques. Voici quelques-uns des types de titane les plus courants:

- Noter 1: Il s'agit de la qualité le plus douce du titane et est principalement utilisée dans les applications où la ductilité et la formabilité du froid sont importantes.

- Noter 2: C'est la note le plus couramment utilisée du titane, principalement à cause de sa force élevée, résistance à la corrosion, et la soudabilité.

- Noter 3: Ceci est similaire à Grade 2, mais avec une amélioration de la résistance à la corrosion.

- Noter 4: Cette note a une force plus élevée que le grade 2 et est couramment utilisé dans les applications qui nécessitent une résistance élevée et un faible poids.

- Noter 5 (Ti 6Al-4V): C'est l'alliage de titane le plus utilisé, avec un rapport force / poids élevé, Bonne résistance à la fatigue, et excellente résistance à la corrosion.

Qu'est-ce que l'acier inoxydable?

Source: https://timesofindia.indiatimes.com

L'acier inoxydable est un type d'acier qui contient un minimum de 10.5% Contenu du chrome par masse. La présence de chrome en acier inoxydable crée un mince, Couche invisible d'oxyde de chrome à la surface, qui est très résistant à la corrosion et à la coloration. Cela fait de l'acier inoxydable un choix populaire pour une large gamme d'applications, y compris appareils de cuisine, Couverts, instruments médicaux, pièces automobiles, et les matériaux de construction.

Autre que sa propriété résistante à la corrosion, L'acier inoxydable est également connu pour sa résistance, durabilité et polyvalence. Il peut être facilement usiné, soudé, et fabriqué, et peut être terminé de différentes manières, y compris le polissage, brossage, et sable.

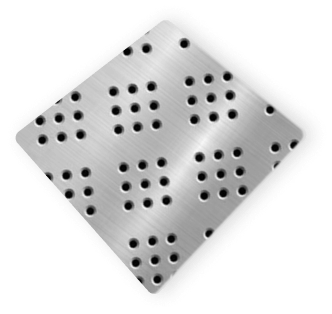

Types d'acier inoxydable

Source: https://SharpsvilleContainer.com

De nombreuses variétés d'acier inoxydable existent, chacun possédant des traits et des caractéristiques distincts. Vous trouverez ci-dessous quelques-uns des types fréquemment rencontrés en acier inoxydable.

- Acier inoxydable austénitique: Il s'agit du type d'acier inoxydable le plus utilisé et contient des niveaux élevés de nickel et de chrome. Il est non magnétique et très résistant à la corrosion.

- l en acier inoxydable ferritique: Cette variété d'acier inoxydable est composée de quantités importantes de chrome et de quantités minimales de carbone, ce qui le rend résilient à la corrosion et à l'oxydation.

- Acier inoxydable martensitique: Cette variété d'acier inoxydable est robuste et robuste, contenant des quantités importantes de carbone et des niveaux de chrome relativement inférieurs.

- Inox duplex: Ceci est un mélange d'acier inoxydable austénitique et ferritique, caractérisé par des quantités importantes de chrome et de faibles niveaux de nickel. Il possède une résistance remarquable contre la corrosion et est fréquemment utilisé dans diverses applications, comme le traitement chimique, Exploration du pétrole et du gaz, et les opérations marines.

Dureté

Source: https://www.arborsci.com

Le titane et l'acier inoxydable sont tous deux des matériaux populaires utilisés dans diverses applications en raison de leurs excellentes propriétés mécaniques, Mais ils diffèrent en termes de dureté.

Le titane a une dureté relativement faible par rapport à l'acier inoxydable. La dureté du titane va de autour 70 pour 150 sur l'échelle de dureté de Brinell (HB), tandis que l'acier inoxydable a une dureté de autour 200 pour 300 HB.

La dureté exacte de ces matériaux dépend de leur composition, traitement, et d'autres facteurs. Cependant, en général, L'acier inoxydable est plus dur que le titane.

Élasticité

Source: https://www.istockphoto.com

Le titane et l'acier inoxydable sont des métaux avec une bonne élasticité, Mais ils ont des propriétés élastiques différentes.

Le titane a un module élastique inférieur que l'acier inoxydable, ce qui signifie qu'il est plus rigide et moins élastique. Le module élastique du titane est autour 110 GPa (gigapascals), qui est environ la moitié de celle de l'acier inoxydable. Cela signifie que le titane se déformera moins sous la même quantité de stress que l'acier inoxydable.

Acier inoxydable, d'autre part, a un module élastique plus élevé que le titane, le rendre plus élastique et flexible. Le module élastique de l'acier inoxydable varie en fonction de l'alliage spécifique, Mais c'est généralement autour 200 GPa.

En résumé, Le titane est plus rigide et moins élastique que l'acier inoxydable en raison de son module élastique inférieur.

Durabilité

Source: https://blog.dahlstromrollform.com

Concernant leur durabilité, L'acier inoxydable et le titane sont extrêmement résistants et peuvent supporter une usure considérable. Néanmoins, Le titane a un rapport force / poids plus élevé par rapport à l'acier inoxydable, ce qui le rend plus approprié pour les situations où le poids est un facteur crucial, comme l'équipement sportif et l'aérospatiale. D'autre part, L'acier inoxydable est mieux adapté aux applications qui nécessitent une résistance exceptionnelle à la chaleur et à la corrosion, comme des ustensiles de cuisine et la construction. Essentiel, Bien que les deux matériaux soient solides et durables, Leurs caractéristiques spécifiques les rendent plus appropriés pour des applications distinctes.

Lester

Source: https://theEngineeringMindset.com

En termes de poids, Le titane et l'acier inoxydable ont des différences distinctes. Le titane est connu pour ses propriétés légères, tandis que l'acier inoxydable est un matériau plus dense et plus lourd.

La densité du titane est approximativement 4.5 g/cm3, qui représente environ la moitié de la densité de l'acier. Cela signifie que le titane est nettement plus léger que l'acier inoxydable. En revanche, La densité de l'acier inoxydable est à propos 7.9 g/cm3, Le rendre beaucoup plus lourd que le titane.

Prix

Source: https://emeritus.org

En général, Le titane est plus cher que l'acier inoxydable. En effet. Le coût du titane peut également varier en fonction de la qualité et de la pureté du métal, ainsi que l'application spécifique pour laquelle il est utilisé. En revanche, L'acier inoxydable est un métal plus courant et plus facilement disponible, ce qui signifie qu'il est généralement moins cher que le titane. Cependant, Le prix de l'acier inoxydable peut également varier en fonction de la qualité et de la finition du métal, ainsi que la demande et l'offre du marché.

En septembre 2022, Le prix moyen du titane pur commercial (noter 2) était autour $8-10 par livre, tandis que les alliages de niveau supérieur tels que Ti 6Al-4V pouvaient aller de $20-30 par livre ou plus. Inversement, le prix moyen pour 304 acier inoxydable (un type commun) était autour $1.50-2.50 par livre sur la même période, tandis que des alliages haut de gamme tels que 316 L'acier inoxydable pourrait aller de $3-5 par livre ou plus.

Applications

Source: https://www.refractorymetal.org

Le titane est un métal léger et fort qui est souvent utilisé dans aérospatial, militaire, et applications médicales. Il est également couramment utilisé dans la production de produits de sport, comme les clubs de golf, En raison de sa force et de sa légèreté. Le titane est également biocompatible, ce qui signifie qu'il peut être utilisé dans les implants médicaux sans provoquer une réaction indésirable dans le corps. Sa résistance à la corrosion le rend idéal pour une utilisation dans les environnements marins également.

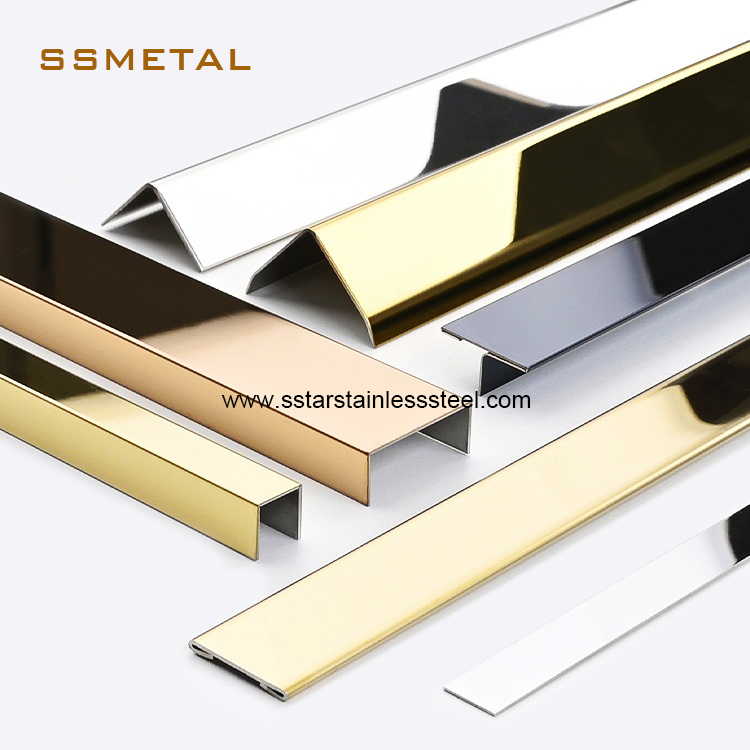

Acier inoxydable, d'autre part, est un matériau populaire dans de nombreuses applications différentes, y compris le industrie alimentaire, construction, et fabrication automobile. Il est fort et résistant à la corrosion, En faire un excellent choix pour les applications où l'hygiène et la durabilité sont importantes. En outre, Produit en acier inoxydable est également relativement abordable, En faire un choix populaire pour les articles ménagers tels que les appareils de cuisine et les couverts.

Afin de produire ces appareils de cuisine, beaucoup Fournisseurs en acier inoxydable ont maintenant offert une feuille en acier inoxydable, connu comme l'un des produits semi-finis de premier plan en acier inoxydable. Et parmi ceux Fournisseurs en tôle en acier inoxydable, une entreprise basée en Chine, SS Metal, Se démarque pour ses technologies pionnières et sa large gamme de produits en acier inoxydable.

Conclusion

Source: https://www.listland.com

En conclusion, Cet article traite des différences entre le titane et l'acier inoxydable. Premièrement, Le titane est plus léger que l'acier inoxydable et a une résistance plus élevée et une résistance à la corrosion. Donc, Le titane est généralement utilisé pour les applications qui nécessitent une résistance à haute résistance et à la corrosion, comme l'aérospatiale et l'équipement médical.

En revanche, L'acier inoxydable est moins cher et fonctionne mieux à basse température. Donc, L'acier inoxydable est généralement utilisé dans des champs tels que la transformation des aliments, construction, et pièces automobiles.

en outre, Le titane est plus difficile à traiter, nécessiter une expertise technique plus élevée et un équipement spécialisé. En même temps, Le titane est également plus cher. Donc, L'acier inoxydable est encore plus populaire dans certaines applications, Même si le titane a de meilleures performances.

En résumé, Le titane et l'acier inoxydable sont deux matériaux très différents qui conviennent à différents champs d'application. Le choix du matériel à utiliser dépend des exigences et du budget spécifiques.