Source: pixabay

Stainless steel finish, which was often used as the appearance of the material, is an important component for many products. So, the choice of an appropriate stainless-steel finish seems to be crucial. It is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. You are probably looking for a long lifespan, corrosion resistance and low maintenance needs. The right finishing is the way to guarantee that stainless steel will behave as expected.

The option usually based on the intrinsic differences between various industries. For example, rough surface fits the process before painting and gluing. Nevertheless, when proceeding to the blending procedure, a smooth surface will be better. For some products value the appearance such as architectures and kitchen applications, the aesthetic of the appearances should be thought first.

Common Stainless-Steel Finishes

Source: pixabay

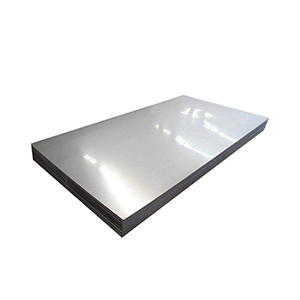

Matte Finish

Matte finish is one of the most common stainless-steel finish. It made from cold rolling stainless steel. To get an overview of this type of finish, we can find that it is not really smooth but it is cheaper than other types of stainless-steel finishes.

Due to its characteristic, it is only used in industries which are not focus on the appearance but more on the practicability. Generally speaking, it is used in architecture when uniformity of finish is not a requirement, such as sewage equipment, refrigeration system, chemical plant equipment, paper mill industry, baking equipment, food processing application and so on.

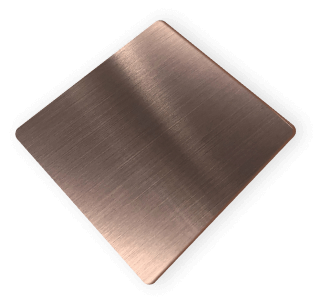

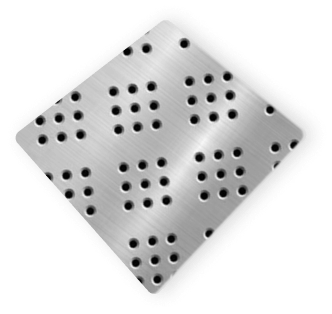

Brushed Finish

Brushed finish, which has been polished by a belt with 120-180 grit. After that, the brushed finish needs to be softened and then it will in the shape.

Compared with matte finish, brushed finish has a good aesthetic. It is smooth, luster and less reflective. So, it is a nice decorative finish for different industries of stainless-steel supplier. For distinguishing manufactures, it can be customized, and several changes make it suits different industries well.

However, there are still some disadvantages for it. The most significant is that the brushed finish reduces corrosion resistance.

Because of its characteristic, its applications are limited. It is often used in jewelry and watches, automotive design, water heaters, air conditioners and other common household utensils.

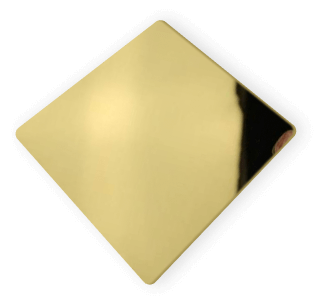

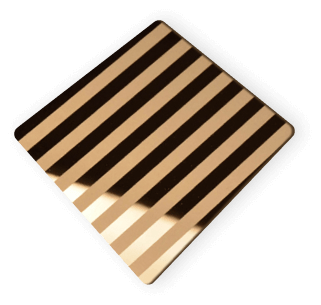

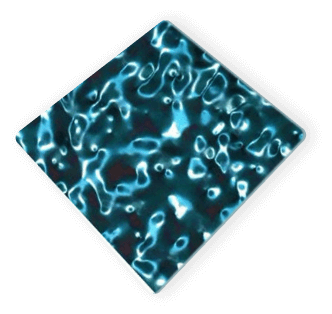

Mirror Finish

Among the three finishes, matte finish, brushed finish and mirror finish, the mirror finish costs a really high expenditure. Nevertheless, it overcomes the problem existed in the matte finish and brushed finish.

The metal covered by mirror finish is very smooth and reflective. It makes cleaning easier. By the way, it gives a chance to mask the aftermath of welding and to hide the surface damage.

At the same time, the mirror finish is conducive to corrosion resistance, which is an update from the brushed finish. Due to its feature, it is widely used in mirrors, column covers, well panels and reflectors.

Factors to Consider

Source: pexels

Different types of stainless-steel product have various requirements for the finish, there are some common considerations below:

Surface Roughness Requirements

Surface roughness is a measure of the texture of a manufactured surface. Roughness can be regarded as tiny channels between a complete machine and the raw material. An appropriate roughness offers the machine a chance to contact the proper oil. On the aesthetic side, roughness depends on reflectivity, either shiny or dull. Within the surface roughness parameters, there are many terms worth looking at.

Aesthetic Preference

A good appearance is crucial for some scenarios especially for the automotive industry. Polishing is often synonymous with high quality.

Polishing refers to using mechanical or chemical to minimize surface roughness, in order to make the surface shinny and flat. The process includes grinding, polishing and restoration.

Corrosion Resistance Needs

For many chemical industries, anti-corrosion is important. The theory of corrosion resistance is to prevent the contact between water and metal surface.

Some types of finish such as mirror finish has good electrical insulation and water barrier, which can cover the metal to play an important role of resisting surrounding media and corrosion. In the opposite, brushed finish may destroy the coating over the metal, and reduce its corrosion resistance.

Hygiene and Cleanliness Consideration

Finish also can be affected by the cleanliness factor. Especially for medical device manufacturing, we should pay attention on the hygiene and cleanliness consideration. Low levels of hygiene may provide an adapt circumstance for germs and promote the growth of bacteria.

When we turn our attention to daily utensil, we should require the finish is get rid of toxic substances attached to human body. Therefore, the harmful substances should be completely removed during the production process.

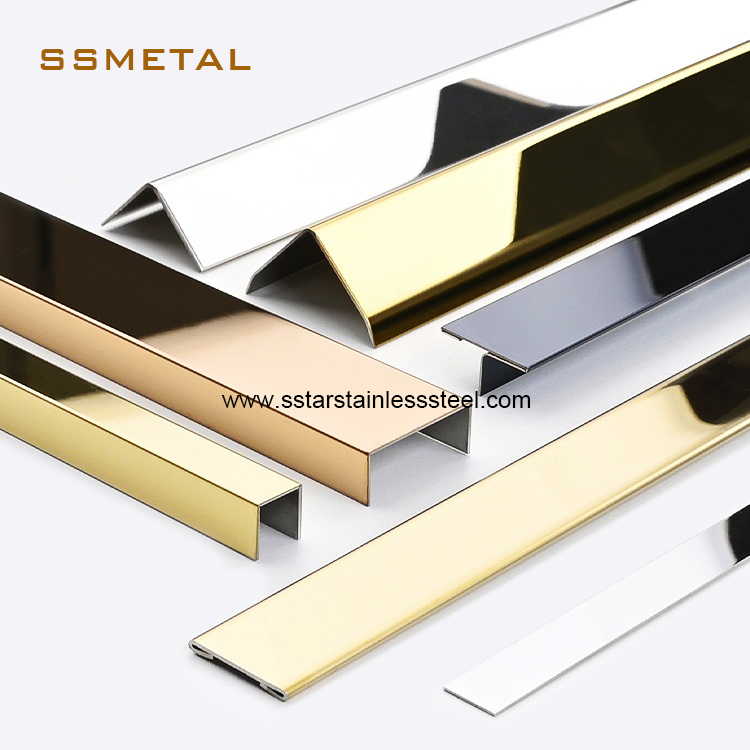

Industry Standards for Stainless Steel Finishes

Source: pixabay

We can have an overview for industry standards for stainless steel finishes through EN Designation. It offers a reference for choosing stainless-steel sheet supplier. All stainless steels are iron-based alloys containing at least 10.5% chromium. A reaction between that chromium and the oxygen in the atmosphere produces a chromium oxide film at the surface. This allows the film to immediately self-repair in the presence of oxygen in the event of any surface damage. The next layer comes at the mill. For mill finishes, there are 1D, 2B, 2D, 2H and so on.

Here are some details:

- 1D: Hot rolled, heat treated and pickled. It has rough surface but free of milling scale.

- 2B: Cold rolled, heat treated, pickled and skin passed. Smooth surface. It is really common in most scenarios, 2B is fundamental for most polished and brushed finishes such as common stainless-steel grades as 201, 304, 304L and 316L.

- 2D: Cold rolled, smooth surface and heat treated and pickled. It achieves a low reflective matte surface appearance which suits industrial and engineering applications. By the way, it has a higher standard of aesthetics than 2B.

- 2H: Work hardened. Cold worked for higher strength. Bright surface.

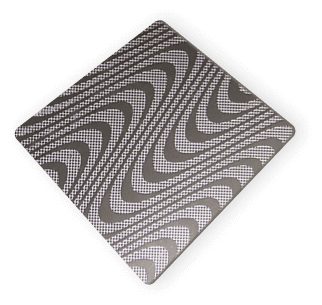

Besides, there is different classifications for patterned and colored finishes standards, such as 2F, 1M, 2M, 2W and so on, here are the descriptions:

- 2F: Cold rolled, heat treated, and skin passed on roughened rolls. Sometimes, bright annealing or annealing and pickling can be performed. It is a uniform matt surface on both sides of the sheet, and it has no few advantages in reflection.

- 1M: Design upon agreement. One side is flat and different textures can be achieved. It is common in building entrances because of the textures, which is helpful to avoid accidents caused by slippery floors.

- 2M: Design upon agreement. One side is flat and fine texture is mainly used for architectural applications.

- 2W: Design upon agreement. These are 2-sided patterned stainless steels in which patterns are rolled or pressed. Both sides with corrugated texture, which increases strength and for aesthetics.

Surface Preparation and Maintenance

Source: pexels

The Importance of Preparations and Maintaince

Surface pollution and deposits may diminish the life span of stainless-steel surface finish and speed up the process of broken. Lots of atmospheres, industrial surroundings, commercial environment and even domestic atmospheres cause deposits adheres to the surface which might be easily corroded.

Therefore, the daily maintenance is necessary. To achieve maximum corrosion resistance the surface of the stainless steel must be kept clean. In fact, if the surfaces are provided with appropriate grade, condition, particular service environment, fabrication and installation procedures, good performance and long life will be achieved. And don’t forget to make a correct and regular cleaning schedules.

The frequency and cost of cleaning of stainless steel are lower than for many other materials and this will often out-weigh higher acquisition costs.

Guidance

There are several different stages including the preparation before installation, the maintenance during installation, routine maintenance and other stages.

It is important to notice that, the period of the routine maintenance is not fixed. This may vary from once to four a times a year for external applications or it maybe once a day for an item in aggressive environment, which is easier to be corroded. Basically, it depends on the atmosphere around the item.

Here are some tools not suitable for the cleaning:

- Tools used with other metals

- Steel storage racks

- Handling equipment

Conclusion

Source: pexels

For many metals, the stainless steel finish is essential. There are different choices due to the variable requirements, which is often consistent with the characteristics of the finish. Matte finish, brushed finish and mirror finish are common in the daily. They are varied from the surface roughness, aesthetic appearance, corrosion resistance and the grade of hygiene and cleanliness. So, their prices are not the same. During the selecting process, we can also follow the industry standards for stainless steel finishes. What’s more, remember cleaning and maintaining your stainless steel finishes regularly.