Stainless Steel Strip

- Home

- >

- Stainless Steel

- >

- Strip

Selective Strips

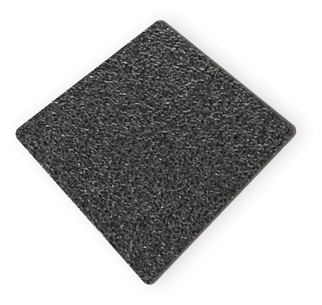

2B

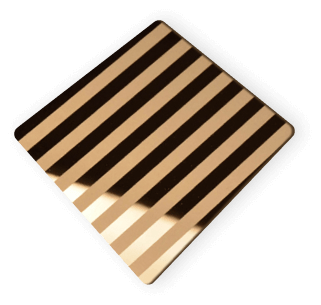

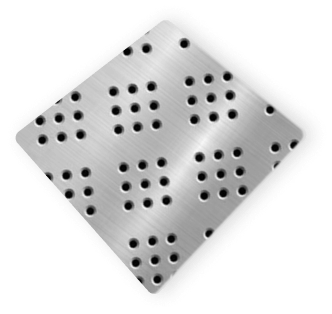

BA

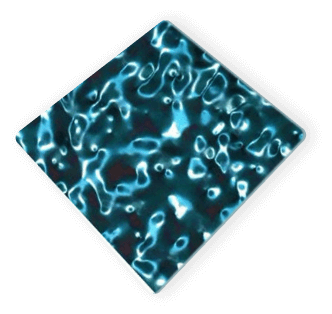

8K

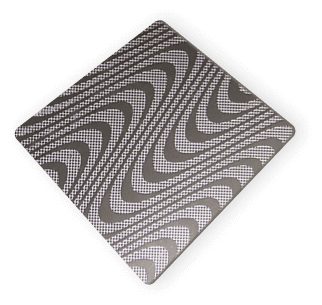

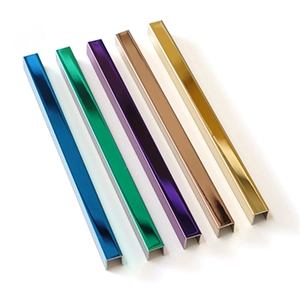

Colored

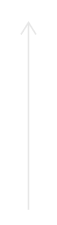

Available Specification

| Stainless Steel Coil Strip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technique | Surface Finish | Grade Series | Thickness(mm) | Width(mm) | Application | |||||

| Main Dimension | ||||||||||

| 10- 600 | ||||||||||

| Hot Rolled | No.1 / 2D | 201 | 2.2-12.0 | Petro-chemical industry,Tanks Construction material | ||||||

| 304 | ||||||||||

| 410 | ||||||||||

| Cold Rolled | 2B | 201/304 | 0.25-3.0 | |||||||

| 410S/430 | 0.25-2.0 | |||||||||

| No.4 / Hairline | 201/304 | 0.22-3.0 | ||||||||

| Mirror / Linen | ||||||||||

| SB | 410S/430 | 0.25-2.0 | ||||||||

| BA | 201/304 | 0.2-1.8 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| 2BA | ||||||||||

Significant Advantage

Enhanced Ductility

Precise Slitting

Typical Applications

Chemical & Food Processing

Pipe Industry

Automobile Industries

Stainless Steel Accessories

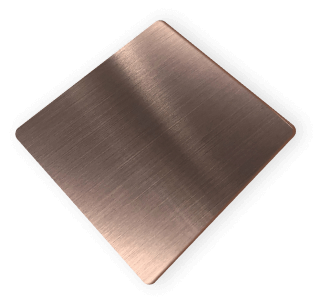

Brushed

Polished

Colored

Ready to Start Your Customization Project?

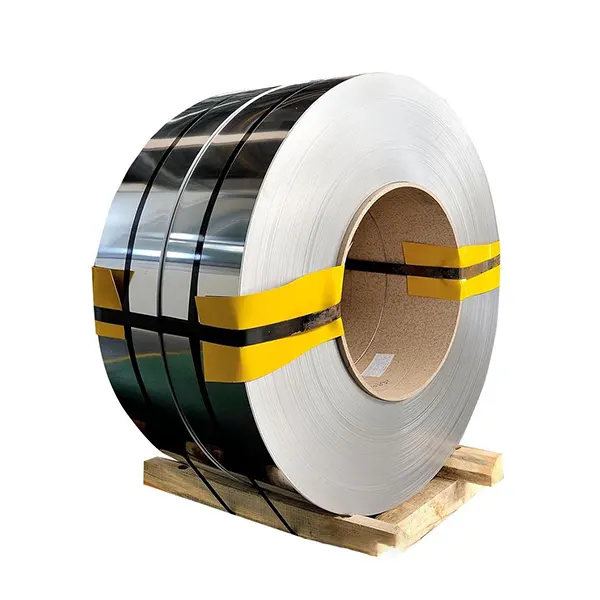

What is Stainless Steel Strip?

Stainless steel strip is a flat, narrow, and continuous metal coil made from stainless steel. It is produced through a process called cold rolling, where stainless steel sheets or coils are further reduced in thickness to achieve the desired dimensions.

Stainless steel strip typically has a thickness ranging from 0.002 inches (0.05 mm) to 0.2 inches (5 mm) and a width ranging from 0.2 inches (5 mm) to 12 inches (305 mm).

Common Applications of Stainless Steel Coil

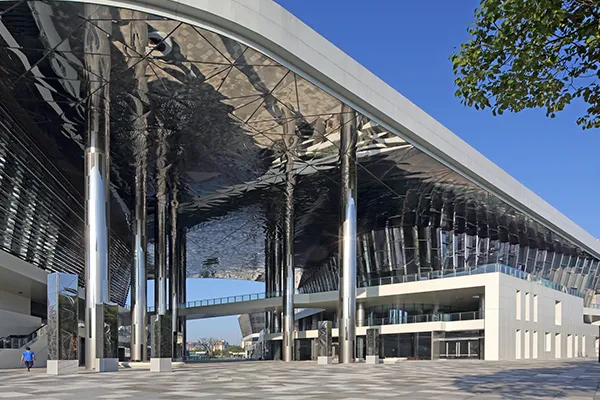

Construction Industry

Medical Instruments

Oil and Gas Industry

Automotive Industry

Kitchen Appliances

Is Stainless Steel Strip Resistant to Corrosion?

Stainless steel strip is highly resistant to corrosion, making it an excellent choice for various applications. The corrosion resistance of stainless steel strip is primarily due to the presence of chromium in its composition. Chromium forms a protective layer on the surface of the steel, known as a passive film or oxide layer. This film acts as a barrier, preventing oxygen and moisture from reaching the underlying metal, thus reducing the risk of corrosion.