One-stop Considerate Service

From the preliminary consultation to bulk production and final shipment, we are committed to tailoring to your desire, solving your specific problems, and offering an instant production schedule if necessary.

- Home

- >

- Service

Begin to Collaborate with Us

Initial Consultation

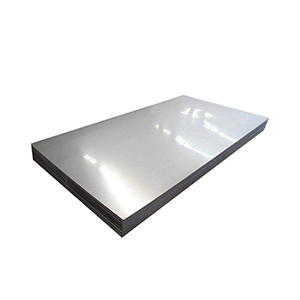

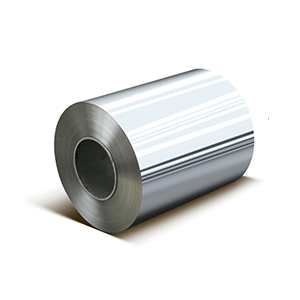

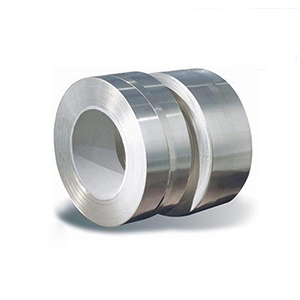

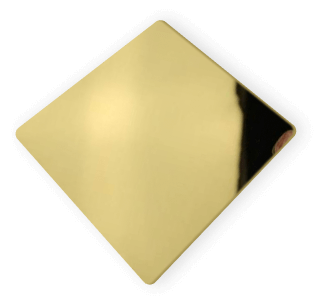

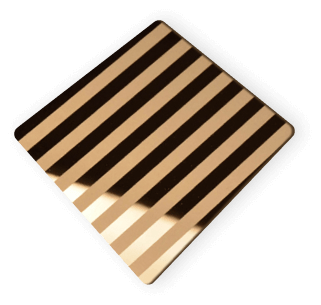

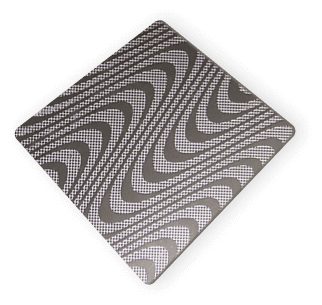

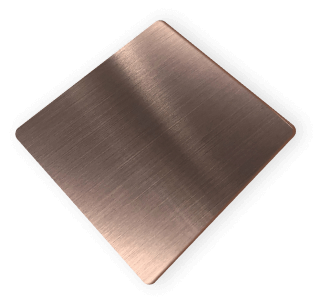

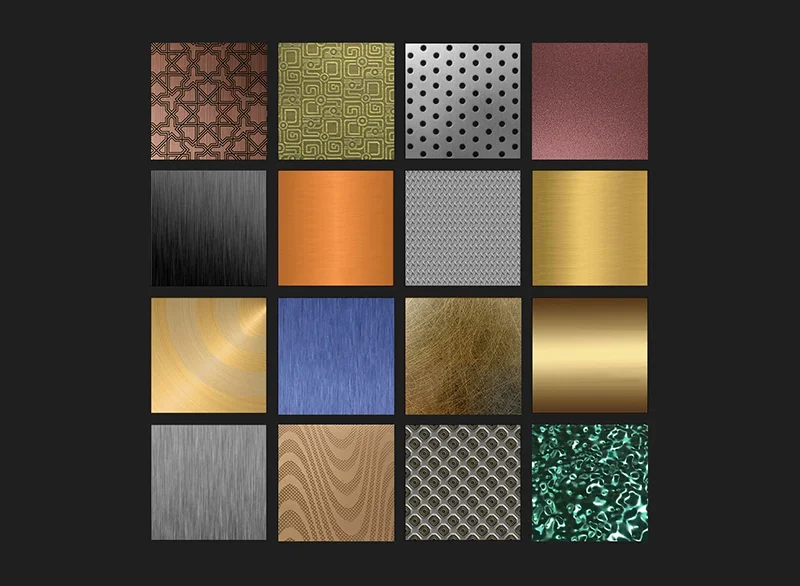

Our professionals will give you a rapid response after listening to your intention regarding pricing, specifications and lead time, etc. When choosing stainless steel materials, you can propose your ideal shape, grade, dimension and finish or send us drawings. Further surface processing is available for you to customize.

Sample Approval

For standard materials, samples are ready.

Welcome your sample or tell us your idea to customized. After making clear your requirements, prototyping will be undertaken. Generally, you can receive the sample 5-7 days after our preliminary consultation. Once the sample is approved, we will carry out the production without hassle.

Bulk Production

Before fabrication, tests are performed on the materials to ensure their quality. Then the machining will be processed to manufacture stainless steel ranging from shapes, grades, dimensions and surface treatments. A series of technology is involved in the manufacturing process.

Meticulous Inspection

After the mass fabrication, our specialists would finely check the completed stainless steel. Width, length, thickness and the exterior appearance are all strictly checked to ensure the standard quality. The surface is guaranteed to be flat, no chromatic aberration and scratch-free.

Secured Packing and Shipping

Packing the goods with waterproof package and strong wooden pallets ensures they avoid damage during the delivery. From start to end, we pay much attention to every single detail so you can trust us.

Aftersales Service

Customers’ receipt of the goods doesn’t mean that our service ends. SSMETAL provides responsive after sales service, we will follow up customer’s usage condition, listen their idea and keep improving our service.