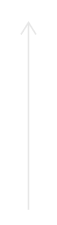

La bobine en acier inoxydable est l'un des matériaux importants. Selon le processus de production, il peut être divisé en deux catégories: bobines d'acier inoxydable laminées à froid et bobines d'acier inoxydable laminées à chaud, et selon différents matériaux, il peut être divisé en austénite, ferrite, martensite, et bobines duplex en acier inoxydable. Comme les autres types d'acier inoxydable, les bobines en acier inoxydable ont une forte résistance à la corrosion et à la rouille, et leur excellente qualité en font des matières premières industrielles et des matériaux de construction importants.

Avec le progrès continu de la science et de la technologie, de nombreux processus de traitement différents sont apparus à la surface des bobines d'acier inoxydable. La surface de l'acier inoxydable a un brillant différent, couleur, motifs, etc. grâce à différentes méthodes de traitement pour améliorer l'apparence de l'acier inoxydable et obtenir des effets esthétiques.

Traitement des surfaces en acier inoxydable

Le traitement de surface de l'acier inoxydable est généralement divisé en deux catégories: l'une est la surface obtenue par les usines de production d'acier inoxydable utilisant différents processus de production, qui est souvent appelé traitement de surface de roulement, l'autre est le traitement de surface des matériaux pour modifier le niveau ou les propriétés de la surface., qui est appelé traitement de la profondeur de la surface en acier inoxydable.

Traitement des surfaces roulantes

Les bobines d'acier inoxydable produites par les laminoirs d'acier passent généralement par un laminage à chaud, laminage à froid, recuit, décapage, finition et autres processus. Parce que la surface des bobines laminées à froid en acier inoxydable occupe une position particulière lors de l'utilisation, leur traitement de surface est divisé en différents types d'usinage de surface (ou des notes) selon différentes méthodes technologiques. Matériaux de bobine en acier inoxydable, en particulier les tôles d'acier et les bandes d'acier laminées à froid, avoir une variété de types de traitement de surface, comme le commun 2B, Surfaces de finition No.1 et BA.

Traitement en profondeur de la surface en acier inoxydable

Pour certaines fins spéciales, les propriétés de surface de l'acier inoxydable doivent être modifiées, la surface en acier inoxydable doit donc être profondément traitée par différents processus. Les processus courants de traitement en profondeur des surfaces en acier inoxydable incluent le brossage, miroir, sablage, placage de titane, gravure, gaufrage, etc.

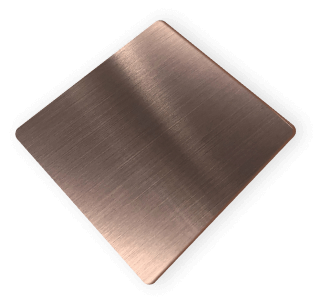

1. Brossé (givré):

Il existe de nombreux types d'acier inoxydable brossé, avec une variété de formes de soie, y compris les lignes de cheveux, sables de flocon de neige, motifs satinés, lignes croisées, etc. Ce traitement de surface donne aux gens une bonne sensation, lustre délicat, forte résistance à l'usure et autres caractéristiques.

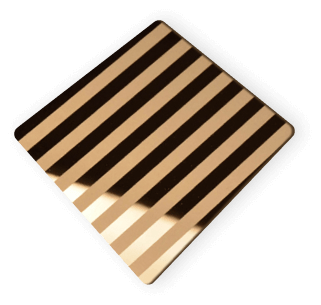

2. Miroir:

Miroir en acier inoxydable, également connu sous le nom d'acier inoxydable à finition miroir 8K, tout comme un miroir, la surface en acier inoxydable est traitée par polissage, et l'effet miroir peut être divisé en meulage général, broyage fin, meulage ultra-précis, etc.

3. Sablage:

Le sablage de l'acier inoxydable donne à la surface de l'acier inoxydable une surface sablée.. La densité de la surface du sable est également divisée en sable fin, sable moyen, grand sable, etc. La densité peut également être produite de différentes manières, formant un effet décoratif unique.

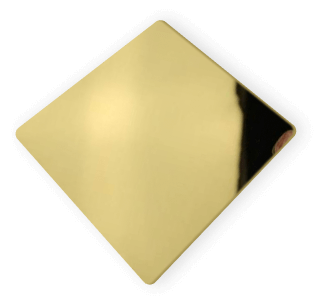

4. Placage de titane:

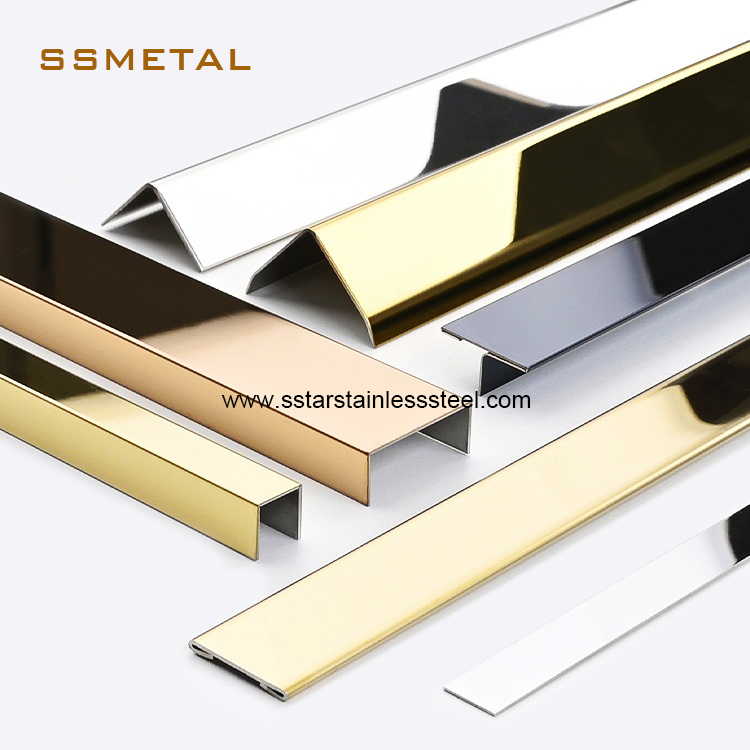

Le processus de placage de titane comprend généralement le placage à l'eau et le placage sous vide., qui est une couche de film ionique qui forme des composés de titane/zirconium à la surface de l'acier inoxydable. La couche de film ionique ne peut pas se décolorer pendant de nombreuses années dans un environnement extérieur. Le placage en titane peut changer l'apparence de l'acier inoxydable dans une variété de couleurs. Il peut être plaqué de bleu saphir, noir, café, rouge, sept couleurs, or, bronze, or rose, champagne or, vert émeraude, etc.

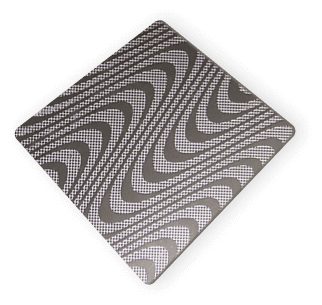

5. Gravure:

L'acier inoxydable gravé utilise une feuille de miroir 8K ou une feuille brossée comme plaque de base. Après gravure, la surface est profondément traitée. Il peut être traité avec la racine des cheveux partielle, titane partiel et autres processus complexes pour obtenir l'effet de motifs clairs et sombres et de couleurs magnifiques.

6. Gaufrage:

L'acier inoxydable gaufré est extrudé sur des plaques d'acier inoxydable à l'aide d'équipements mécaniques et de moules à motifs de précision., de sorte que des motifs concaves et convexes apparaissent sur la surface de la plaque, comme les plaques à carreaux communes, plaques de diamant, etc. Il existe également récemment une plaque en acier inoxydable ondulée à l'eau très populaire., qui est aussi une sorte de plaque en relief.

Applications

Avec le développement continu de l'économie nationale, le champ d'application des bobines en acier inoxydable devient de plus en plus étendu, et les perspectives du marché sont très optimistes de la part des initiés de l'industrie.

De l'analyse de l'industrie d'application des bobines d'acier inoxydable, L'industrie automobile est actuellement le domaine d'application des bobines d'acier inoxydable qui connaît la croissance la plus rapide.. Au cours de la dernière décennie, la consommation de bobines d'acier inoxydable pour automobiles est passée d'une moyenne de 10 kg à 30 kg au Japon et plus de 40 kg aux États-Unis. Les bobines en acier inoxydable sont également largement utilisées dans les véhicules de transport public tels que les bus., métros et trains à grande vitesse. L’industrie chinoise des appareils électriques constitue un marché potentiel important pour l’application de bobines en acier inoxydable.. en outre, la demande de serpentins en acier inoxydable dans l'industrie de l'eau, industrie de la construction et des structures, l'industrie de la protection de l'environnement et les installations industrielles augmenteront également d'année en année.

je. Industrie automobile/automobile

Il s’agit du domaine d’application des bobines d’acier inoxydable qui connaît la croissance la plus rapide. L'utilisation d'une bobine en acier inoxydable à haute résistance pour fabriquer la structure de la carrosserie peut réduire considérablement le poids du véhicule et améliorer la résistance de la structure de la carrosserie.. L'utilisation de bobines en acier inoxydable pour fabriquer le panneau et les pièces décoratives du véhicule peut réduire les coûts de maintenance. en outre, la bobine en acier inoxydable est également utilisée dans le système d'échappement des automobiles en raison de sa résistance à la corrosion des ions chlorure et de sa résistance à la chaleur. Aujourd'hui, Japon, les États-Unis, La Suède et d'autres pays ont largement utilisé des véhicules à bobines en acier inoxydable. Le Japon en fait la promotion depuis les années 1980, et ses wagons en acier inoxydable ont atteint 60%. L’industrie automobile est au centre du développement d’applications de bobines en acier inoxydable.

II. Industrie aquatique

La pollution de l’eau lors de son stockage et de son transport a suscité une grande attention. Un grand nombre de pratiques ont prouvé que le serpentin en acier inoxydable est le meilleur matériau pour la préparation de l'eau., stockage, transport, purification, régénération, dessalement de l'eau de mer et autres industries de l'eau. Ses avantages sont la résistance à la corrosion, résistance aux tremblements de terre, économie d'eau, hygiène (sans rouille et sans patine), poids léger (réduction d'un tiers), moins d'entretien, longue durée de vie (40 années) faible coût du cycle de vie (CCV), et matériau de protection de l'environnement vert recyclable. Selon les rapports, le bobinage de tuyaux en acier inoxydable à Tokyo, Japon, a atteint 76%, et le taux de fuite des pipelines a diminué de 14.7% pour 7.5% à l'heure actuelle. Après le grand tremblement de terre d'Osaka, Japon, le réservoir de stockage d'eau du serpentin en acier inoxydable était intact. Récemment, Le Japon a développé des joints à soufflet, réduire le coût de construction des conduites d'eau en acier inoxydable en 20%, le coût total par 3%, et le coût d'entretien par 3/4.

III. Industrie du bâtiment

C'est l'une des premières applications des bobines en acier inoxydable.. En termes de décoration architecturale, à l'heure actuelle, la bobine en acier inoxydable est principalement utilisée dans les murs extérieurs, colonnes intérieures et extérieures d'immeubles de grande hauteur, main-d'œuvre, étages, panneaux muraux d'ascenseur, portes et fenêtres, murs-rideaux et autres décorations et composants internes et externes. La bobine en acier inoxydable, dont la surface a été traitée, coloré et enduit, résout le problème des empreintes de mains faciles après avoir touché, et élargit encore le champ d'application de la bobine en acier inoxydable. Le Japon a développé une variété de matériaux de toiture en bobines d'acier inoxydable, comme une résistance élevée à la corrosion, ferrite moyenne et diverses plaques de revêtement. La bobine en acier inoxydable à surface de brosse ultra propre développée en Suède et le panneau UGITOP développé par Ugine en France offrent de nouvelles options pour le secteur de la construction..

IV. Appareils électroménagers

Dans l'industrie de l'électroménager, la grande quantité de bobines en acier inoxydable constitue le cylindre intérieur de la machine à laver automatique, le réservoir intérieur du chauffe-eau, la coque intérieure du four à micro-ondes, et le revêtement intérieur du réfrigérateur, et la plupart d'entre eux utilisent de l'acier inoxydable ferrite. La proportion d’acier inoxydable pour les appareils électroménagers en Europe occidentale est relativement importante, et l'Asie est généralement moins utilisée sauf le Japon, qui est proche du niveau européen.

Dans 1999, la consommation de ferrite et d’acier inoxydable martensitique dans l’industrie japonaise de l’électroménager a atteint 28%, et l'austensite représentaient 12%. Fours à micro-ondes, réfrigérateurs, climatiseurs, Téléviseurs, etc. produits en Chine sont devenus des produits d'exportation compétitifs dans le monde, et l'industrie de l'électroménager constitue un marché potentiel pour les applications en acier inoxydable.. On estime que dans le prochain 5-10 années, la demande d’acier inoxydable dans l’industrie électrique chinoise atteindra 100,000-150,000 tonnes.

V. Industrie de la protection de l'environnement

Gaz résiduaires industriels, les usines de traitement des ordures et des eaux usées doivent être constituées de serpentins en acier inoxydable. En cours de désulfuration des fumées, afin de résister à la corrosion du dioxyde de soufre, ions chlorure et ions fer, des bobines en acier inoxydable duplex et des bobines en acier inoxydable austénitique de haute qualité sont nécessaires dans les tours d'absorption, refroidisseurs, pompes, vannes, conduits de fumée, etc. Incinérateurs de déchets, le traitement des eaux usées et d'autres installations doivent être constitués de matériaux de serpentins en acier inoxydable haute performance.

VI. Installations industrielles

La proportion de bobines d'acier inoxydable utilisées dans les installations industrielles des pays développés peut généralement atteindre 15%-20%, et la proportion de demandes nationales est encore très faible. D'une part, grâce à l'introduction d'un ensemble complet d'équipements industriels, les matériaux des bobines en acier inoxydable ne sont pas comptés, et d'autre part, les matériaux domestiques n'ont pas été adoptés. Des bobines en acier inoxydable sont nécessaires dans les domaines de la chimie, produits pétrochimiques, fibres chimiques, fabrication du papier, nourriture, médecine, énergie (énergie nucléaire, puissance thermique, piles à combustible) et d'autres domaines. Avec l'amélioration de la qualité des produits nationaux en bobines d'acier inoxydable et le développement de produits de marque spéciale, l'application de bobines d'acier inoxydable dans les installations industrielles augmentera d'année en année.