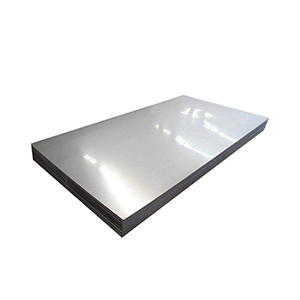

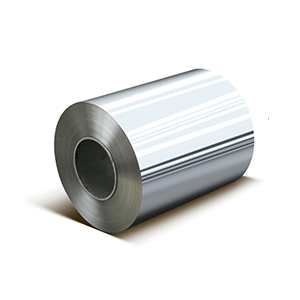

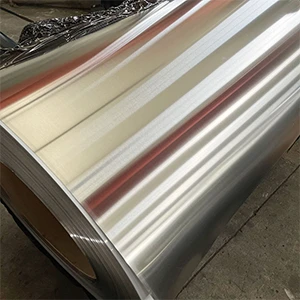

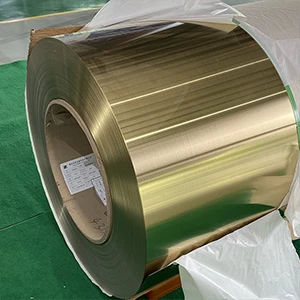

Bobina de acero inoxidable

- Hogar

- >

- Acero inoxidable

- >

- Bobina

Bobinas selectivas

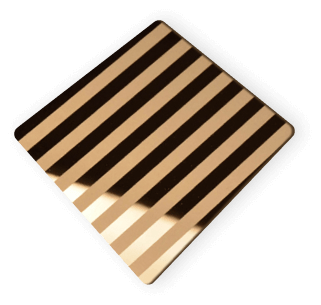

2B

No.1

licenciado en Letras

8k

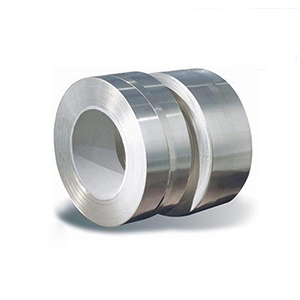

Especificaciones disponibles

| Información de la bobina de acero inoxidable | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Técnica | Acabado de la superficie | Serie de grados | Espesor(milímetros) | Ancho(milímetros) | Solicitud | |||||

| Dimensión principal | ||||||||||

| 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 | |||||

| Laminado en Caliente | No.1 /2E | 201/202/ 304 | 2.2-12.0 | Industria petroquímica Tanques Material de construcción | ||||||

| Laminado en frío | 2B | 201/304 | 0.25-3.0 | |||||||

| 410S/430 | 0.25-2.0 | |||||||||

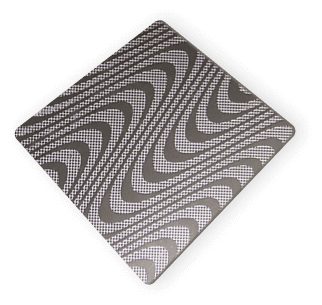

| No. 4 / Espejo rayita / Lino SB | 201/304 | 0.22-3.0 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| licenciado en Letras | 201/304 | 0.2-1.8 | ||||||||

| 410S/430 | 0.25-2.0 | |||||||||

| 2licenciado en Letras | ||||||||||

| Composición química y propiedades mecánicas de la bobina de acero inoxidable. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Calificación | Composición química (%) | Rendimiento mecánico | |||||||||

| C | Y | Minnesota | PAG | S | En | cr | Mes | Dureza | |||

| 201 | ≤0,15 | ≤1,00 | 5.5/7.5 | ≤0,060 | ≤0,030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241, HRB≤100, HV≤240 | ||

| 304 | ≤0,08 | ≤1,00 | ≤2.0 | ≤0,045 | ≤0,03 | 8.0/11.0 | 18.00/20.00 | - | HB≤187, HRB≤90, HV≤200 | ||

| 316 | ≤0,08 | ≤1,00 | ≤2.0 | ≤0,045 | ≤0,03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90, HV≤200 | ||

| 316l | ≤0,03 | ≤1,00 | ≤2.0 | ≤0,045 | ≤0,03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90, HV≤200 | ||

| 410 | ≤0,15 | ≤1,00 | ≤1,25 | ≤0,060 | ≤0,030 | ≤0,060 | 11.5/13.5 | - | HB≤183, HRB≤88, HV≤200 | ||

| 430 | ≤0,12 | ≤1,00 | ≤1,25 | ≤0,040 | ≤0,03 | - | 16.00/18.00 | - | HB≤183, HRB≤88, HV≤200 | ||

Ventaja significativa

Flexible

Conveniente

Aplicaciones Típicas

Equipos industriales

Equipo electrónico.

Batería de cocina

Maquinaria

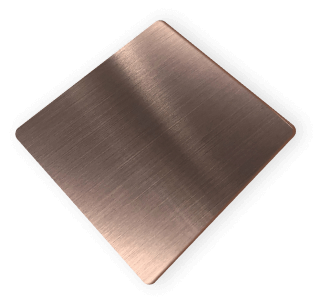

cepillado

Pulido

De colores

en relieve

Listo para iniciar su proyecto de personalización?

Diferentes grados de bobinas de acero inoxidable

Calificación 201 es una alternativa de menor costo 304. Ofrece buena formabilidad., resistencia a la corrosión moderada, y se utiliza a menudo en aplicaciones que requieren atractivo estético., como utensilios de cocina, se hunde, y utensilios.

Calificación 304 Es el grado de acero inoxidable más común y ampliamente utilizado para bobinas.. Ofrece una excelente resistencia a la corrosión., buena formabilidad, y es adecuado para una variedad de aplicaciones en industrias como la de procesamiento de alimentos, químico, y arquitectónica.

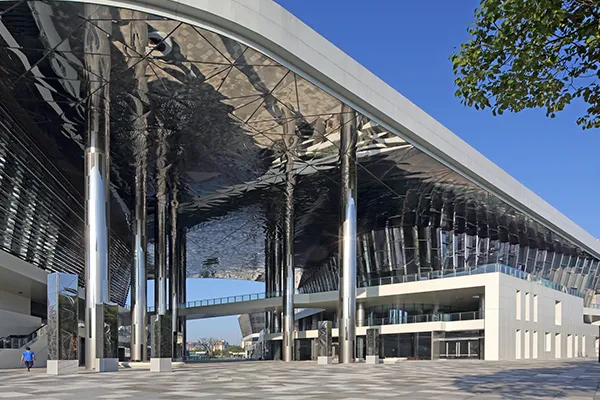

Calificación 316 es conocido por su resistencia a la corrosión superior en comparación con 304. Contiene molibdeno, lo que mejora su resistencia a la corrosión química, haciéndolo ideal para su uso en ambientes marinos, equipo farmaceutico, y arquitectura costera.

Calificación 410 Es un acero inoxidable martensítico conocido por su alta resistencia., dureza, y resistencia a la corrosión. Ofrece buenas propiedades mecánicas y puede endurecerse mediante tratamiento térmico.. Calificación 410 Se utiliza comúnmente en aplicaciones como cubiertos., instrumentos dentales y quirúrgicos, y válvulas.

Este grado de acero inoxidable ferrítico proporciona buena resistencia a la corrosión y al calor.. Se utiliza comúnmente en aplicaciones como adornos de automóviles., electrodomésticos de interior, y componentes arquitectónicos.

Aplicaciones comunes de la bobina de acero inoxidable

Construcción & Arquitectura

Maquinaria Industrial

Químico & Petroquímico

Procesamiento de alimentos & Abastecimiento

Automoción y Transporte

Preguntas frecuentes

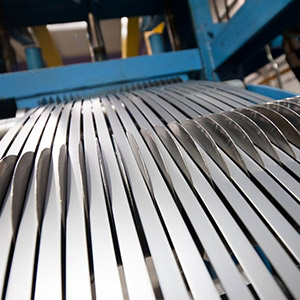

La bobina de acero inoxidable se refiere a una tira continua de acero inoxidable que se enrolla en forma de bobina.. Se utiliza comúnmente en diversas industrias para aplicaciones de fabricación, como el conformado de chapa metálica., fabricación, y como materia prima para su posterior procesamiento..

Las bobinas de acero inoxidable poseen varias propiedades clave, incluyendo alta resistencia a la corrosión, resistencia y durabilidad, resistencia al calor, higiene y limpieza, y atractivo estético. También son conocidos por sus bajos requisitos de mantenimiento y su versatilidad en diversos procesos de fabricación..

Las bobinas de acero inoxidable generalmente se fabrican mediante un proceso conocido como laminación en frío.. Se trata de pasar una tira de acero inoxidable a través de un conjunto de rodillos para reducir su espesor y darle forma de bobina.. La laminación en frío ayuda a mejorar las propiedades mecánicas del material., precisión dimensional, y acabado superficial.

Sí, La bobina de acero inoxidable es altamente reciclable.. Al final de su ciclo de vida o cuando ya no sea necesario, Se puede recoger la bobina de acero inoxidable., procesado, y reciclado. El acero inoxidable conserva sus propiedades incluso después del reciclaje., y el proceso se puede repetir varias veces sin una degradación significativa de la calidad..