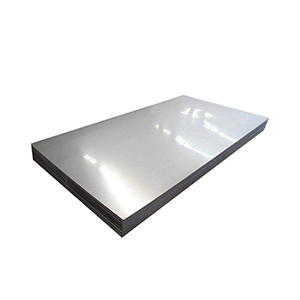

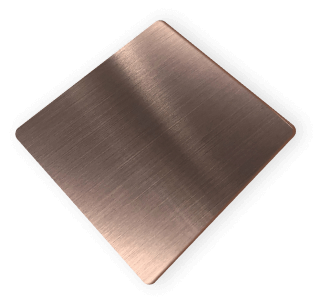

El acabado fino de acero inoxidable es una textura sedosa en la superficie de la placa de acero inoxidable., que es uno de un proceso de procesamiento de placa de acero inoxidable. La superficie es mate.. Si miras con atención, hay un rastro de textura en él, pero no puedes tocarlo. Es resistente al desgaste que las placas de acero inoxidable brillantes ordinarias y tiene un aspecto de mayor calidad..

El proceso de trefilado perderá hasta cierto punto el espesor de la placa de acero inoxidable., generalmente 0,1~0,2 mm. Además, debido a la fuerte secreción de grasa y sudor del cuerpo humano, especialmente la palma de la mano, La lámina de acero inoxidable con acabado fino dejará huellas dactilares más evidentes y deberá frotarse con regularidad..

El tratamiento superficial de la mayoría de las láminas de acero inoxidable es adecuado para el pulido mate., brillo y reflejo, y hay algunos adecuados para la línea del cabello. Estas placas de acero inoxidable aptas para moler se conocen comúnmente como placas de acero inoxidable cepillado..

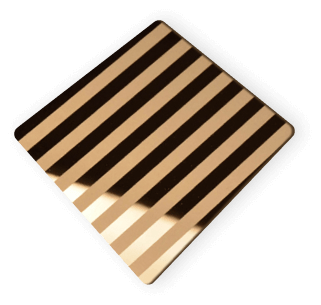

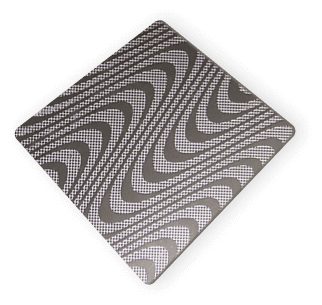

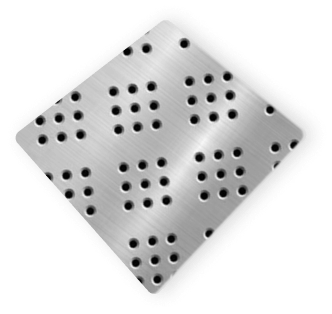

La chapa de acero inoxidable cepillado generalmente tiene varios efectos.: Hoja de acero inoxidable fina, copo de nieve/NO.4, patrón SB. Un patrón de seda recto es un patrón ininterrumpido de arriba a abajo como la línea del cabello.. En general, la pieza de trabajo de la máquina trefiladora fija se puede mover hacia adelante y hacia atrás. Patrón de copo de nieve (Hoja de acero inoxidable NO.4) es el más popular hoy en día. Consta de un pequeño punto regular., que se puede conseguir con lija de gusano.

El patrón SB se compone de líneas de diferentes longitudes.. Porque la textura de la rueda de nailon es suave., Se puede moler en partes irregulares para alcanzar el patrón de nailon..

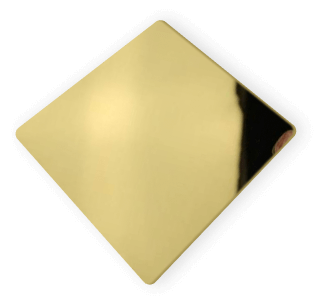

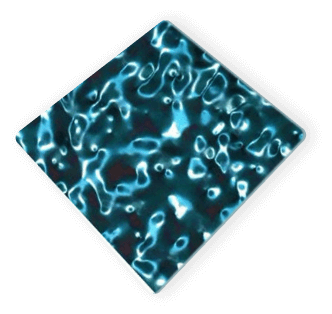

El tablero cepillado generalmente se refiere al patrón de superficie más un término general. En el pasado, se llamaba tablero esmerilado. La textura de la superficie incluye líneas rectas., líneas turbulentas, ondas e hilos. Hojas de acero inoxidable cepilladas de color, como acero inoxidable fino negro., línea de cabello de bronce acero inoxidable línea de cabello de oro inoxidable es una superficie de varios colores obtenida mediante revestimiento de agua no electrolítico o recubrimiento de iones al vacío en la superficie del sustrato de una placa de acero inoxidable cepillado.

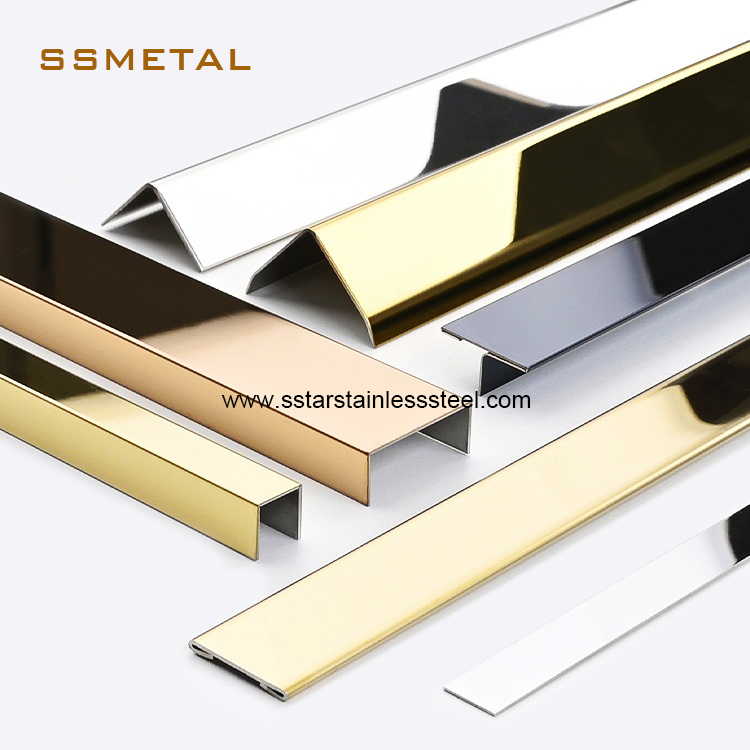

Hay muchos lugares donde se utilizan placas de acero inoxidable en la vida.. Por ejemplo, Paneles de muebles de baño en nuestros baños., paneles de gabinetes de cocina, fregaderos de acero inoxidable, y decoración de hotel o hogar con láminas de acero inoxidable cepillado negro, hojas de acabado de cepillo ss, o paneles de acero inoxidable cepillado. Todos ellos están hechos de placas de acero inoxidable..

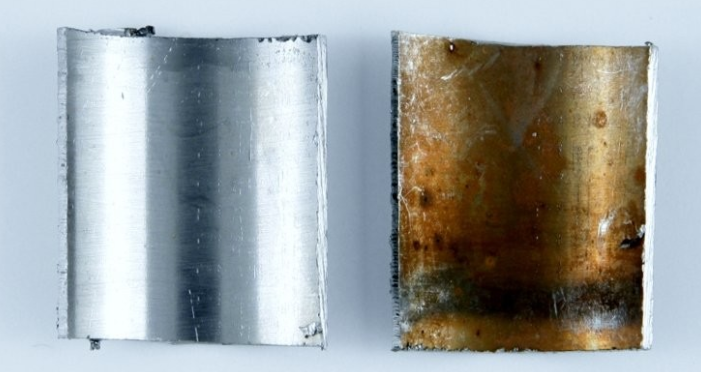

Ahora surge el problema, eso es, Los requisitos de proceso de las personas se han vuelto más altos., que también diversificó las formas del producto, como tubos trefilados, tubos chapados en titanio con línea fina de oro inoxidable o línea fina negra de acero inoxidable y lámina de acero inoxidable cepillado cortada a medida, etc., ¿La resistencia a la oxidación de las láminas de acero inoxidable después del trefilado??

1. Hoja de acero inoxidable No es fácil de oxidar debido a la película protectora formada por níquel en la superficie. para que la placa no entre en contacto fácilmente con sustancias como el oxígeno en el aire. Entonces no es fácil oxidarse. Bien, Ahora se ha realizado el procesamiento de trefilado., Convertir el espejo original en un tablero de trefilado., y la superficie está dañada. Aunque todavía tiene función antioxidante., la resistencia a la corrosión se ha debilitado.

2. Informar al usuario que preste atención al medio ambiente.. No lo uses al aire libre.. Si está erosionado por el polvo y la lluvia., es fácil de oxidar. El trefilado de placas de acero inoxidable se considera principalmente para uso en interiores., Para mantener la belleza y la vida útil del producto..

3. Mantenimiento de placa de acero inoxidable cepillado.. Esto es relativamente importante. Generalmente, Preste atención a no entrar en contacto con sustancias ácidas y básicas., Y preste atención a la prevención de la humedad y la limpieza del polvo..